本帖最后由 超级盾 于 2016-5-10 20:36 编辑

Final Assembly and FirstRun!

Having had much of the month of October free, I was able to make good progress in putting the engine together. The results are shown below.

As for the running, please bear in mind I have never run a model turbine before!

5bears制作Wren MW54涡喷发动机

I did not photograph any of the operations dealing with the outer case. Somewhere during construction, my engine "stretched" a bit and I couldn't use the Wren outer case wrap. I had already ordered some 0.4mm sheet stainless, so a bit of work with the shears produced an acceptable case... up to the point where I began to weld the seam. I apparently overheated the steel a bit and the case was hopelessly warped. Case #2 turned out nicely. One bit of warning: when you drill the holes to secure the case front and rear, it might be tempting to locate and drill the holes with the part in place to assure perfect alignment of the holes. The problem with this is that the burr produced in the case is both large and strong, and it will secure either the case front or rear inside very effectively, requiring a mallet to remove. I did some damage to my case rear in this way. So be sure to drill your holes in the case while the steel is still flat, or you can turn a piece of aluminum to a snug sliding fit to act as a sacrificial support member for the drilling operation.

5bears制作Wren MW54涡喷发动机

I found that my diffuser would slide nicely from rear to front in the outer case, so I assembled the "guts" of the engine on my bench. In these two photos, one can see the cast NGV, case rear, combustion chamber, and diffuser properly assembled. On the top of the diffuser, you can also see the 4 service port screws which will later accept my 10-32 adapters for fuel, oil, gas, and air.

With the assembly slid into the case, the case rear was secured. I used 12, 3-48 button head cap screws for better sealing. The front bearing was installed, as well as the shaft seal. Silicon grease helped this along.

From the rear, I inserted the preload spring and tube into the shaft tunnel. The tube projected a bit under spring power, making insertion of the rotor tricky. I used finger pressure on the compressor spacer/oil seal on the inner race of the front bearing to keep the front bearing together! With care, there is no danger of the balls popping free.

5bears制作Wren MW54涡喷发动机

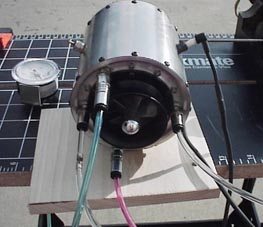

Together at last! Note one glow plug and one spark plug. I was going to try a spark ignition to see if it is a viable means to ignite the engine. The three lower ports are the standard fuel, lube, and propane inlets. The fourth connector is for measuring case pressure. For now, there is no revs counter attached.

5bears制作Wren MW54涡喷发动机

I made use of the exact same ring I used to secure the cast NGV for turning to create a quick and dirty mount. Two additional holes were drilled, and a pair of 3/16" mild steel rods were inserted, TIG welded, and bent. Initial runs were made cone-off.

5bears制作Wren MW54涡喷发动机

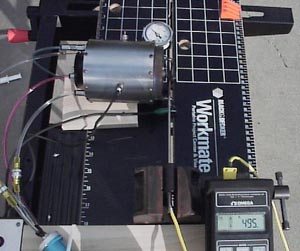

On the stand at last! The board does nothing except support the nose of the engine. The two rods from the photo above were clamped in the workmate vise jaws. A second board c-clamped to the workmate held a liter of fuel, the fuel pump, speed controller, servo driver, and battery. The propane cannister was clamped to the legs of the stand.

And the moment of truth had arrived! I was using a compressed air tank to spool the engine, and was surprised at the amount of air required to get it to spin up. After assembly, I had noticed that the rotor was a bit draggy, but assumed that it was the preload, and after verifying that the rotor was running free of interference from both the oil seal and the intake cone, I decided to give it a shot. Per the manual, I spun up the rotor, turned on the gas, and tried to get some ignition. Nothing from the spark, ditto the glo-plug. Grrr. Out came a small propane torch to get some ignition the manly way, via flames at the rear.

Spun up again, I removed the air, let it spin down, and touched off the gas. Whooomp! Wow! Add more air and gas! I watched in horror as the revs decayed and the EGT began to skyrocket through 650! I groped for the gas valve and shut it down, all in seeming slow motion. I had visions of molten parts spewing out the rear through a fractured turbine wheel. Something was seriously amiss.

After a few seconds, I felt better, as I realized I had left my EGT meter in fahrenheit! Ooops! Heh heh. But the rotor was still too stiff, and regardless of the EGT, the engine wasn't accelerating.

Back on the bench, I removed the rotor assembly, and discovered the preload spring had been fouling the shaft. Mike Murphy, the Wren genius, had WARNED me of this possibility in an email yesterday, and sure enough it had happened to me. The shaft was lightly scored but still entirely useable. I installed a second preload spring made to better tolerances, and was entirely gratified to feel a nice, smooth spin with much less drag than before.

5bears制作Wren MW54涡喷发动机

Mounted again, I repeated the entire process. Spin up, add gas, ignite, replace air, and watch as the EGT gently rises and the engine accelerates! Mike had also warned me to add the fuel slowly. This I did, and the fuel touched off with a nice Whump and my little Wren began to sing!

Not having a rev counter, I limited my case pressure to 14 psi or about .95 bar, which produced the photo as shown... EGT 495 celsius. The sound was sweet, and the engine behaved perfectly.

I'm sorry I didn't take any thrust measurements, but stay tuned, I will get these ASAP.

Thank you Wren for this fine little engine!

|

![]()