马上注册,结交更多好友,享用更多功能,让你轻松玩转社区。

您需要 登录 才可以下载或查看,没有账号?立即注册

×

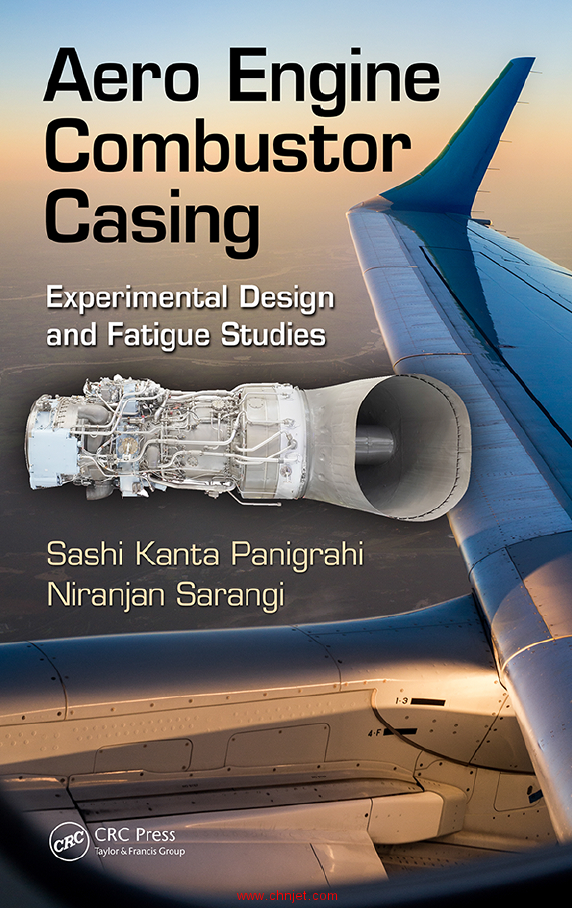

《Aero Engine Combustor Casing: Experimental Design and Fatigue Studies》

航空发动机燃烧室壳体:实验设计与疲劳研究

作者:

Sashi Kanta Panigrahi

Niranjan Sarangi

出版社:CRC

出版时间:2017年

《Aero Engine Combustor Casing: Experimental Design and Fatigue Studies》

《Aero Engine Combustor Casing: Experimental Design and Fatigue Studies》

《Aero Engine Combustor Casing: Experimental Design and Fatigue Studies》

《Aero Engine Combustor Casing: Experimental Design and Fatigue Studies》

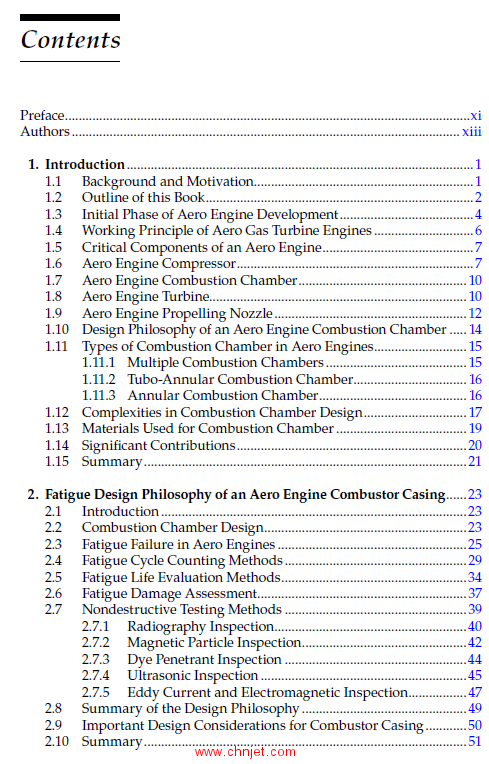

目录

Preface.......................................................................................................................xi

Authors.................................................................................................................. xiii

1. Introduction......................................................................................................1

1.1 Background and Motivation................................................................1

1.2 Outline of this Book...............................................................................2

1.3 Initial Phase of Aero Engine Development........................................4

1.4 Working Principle of Aero Gas Turbine Engines..............................6

1.5 Critical Components of an Aero Engine.............................................7

1.6 Aero Engine Compressor......................................................................7

1.7 Aero Engine Combustion Chamber.................................................. 10

1.8 Aero Engine Turbine........................................................................... 10

1.9 Aero Engine Propelling Nozzle......................................................... 12

1.10 Design Philosophy of an Aero Engine Combustion Chamber...... 14

1.11 Types of Combustion Chamber in Aero Engines............................ 15

1.11.1 Multiple Combustion Chambers.......................................... 15

1.11.2 Tubo-Annular Combustion Chamber.................................. 16

1.11.3 Annular Combustion Chamber............................................ 16

1.12 Complexities in Combustion Chamber Design............................... 17

1.13 Materials Used for Combustion Chamber....................................... 19

1.14 Significant Contributions....................................................................20

1.15 Summary............................................................................................... 21

2. Fatigue Design Philosophy of an Aero Engine Combustor Casing.......23

2.1 Introduction..........................................................................................23

2.2 Combustion Chamber Design............................................................23

2.3 Fatigue Failure in Aero Engines........................................................25

2.4 Fatigue Cycle Counting Methods......................................................29

2.5 Fatigue Life Evaluation Methods.......................................................34

2.6 Fatigue Damage Assessment.............................................................. 37

2.7 Nondestructive Testing Methods...................................................... 39

2.7.1 Radiography Inspection.........................................................40

2.7.2 Magnetic Particle Inspection.................................................42

2.7.3 Dye Penetrant Inspection......................................................44

2.7.4 Ultrasonic Inspection.............................................................45

2.7.5 Eddy Current and Electromagnetic Inspection..................47

2.8 Summary of the Design Philosophy.................................................49

2.9 Important Design Considerations for Combustor Casing.............50

2.10 Summary............................................................................................... 51

3. Development of Test Facility and Test Setup..........................................53

3.1 Introduction..........................................................................................53

3.2 Airworthiness and Certification........................................................55

3.3 Description of the Test Facility and Its Subsystems........................56

3.3.1 Hydraulic Power Supply........................................................ 57

3.3.2 Servo Valve with Manifold....................................................58

3.3.3 Safety Relief Valve..................................................................59

3.3.4 Servo Controller......................................................................59

3.3.5 Pressure Transducer...............................................................59

3.4 Integration of the Subsystems............................................................60

3.5 Design and Manufacturing of Adaptors.......................................... 61

3.5.1 Bottom Fixing Plate................................................................ 62

3.5.2 Bottom Sealing Drum............................................................ 62

3.5.3 Inner Bottom Fixing Plate......................................................63

3.5.4 Special Tie Rod........................................................................64

3.5.5 Top Sealing Plate.....................................................................65

3.5.6 Top Fixing Plate.......................................................................65

3.5.7 Top Support Plate....................................................................65

3.5.8 Top Holding Plate...................................................................66

3.5.9 Special Studs............................................................................ 67

3.5.10 Seals..........................................................................................68

3.6 Summary...............................................................................................68

4. Manufacturing of an Aero Engine Combustor Casing,

the Experimental Evaluation of Its Fatigue Life, and

Correlation with Numerical Results......................................................... 69

4.1 Introduction.......................................................................................... 69

4.2 Manufacturing Method of the Combustor Casing......................... 70

4.2.1 Metal Spinning Process......................................................... 70

4.2.1.1 Advantages of the Metal Spinning Process.........71

4.2.1.2 Disadvantages of Metal Spinning Process..........72

4.2.2 Electron Beam Welding Method..........................................72

4.2.3 Tungsten Inert Gas Welding Method................................... 74

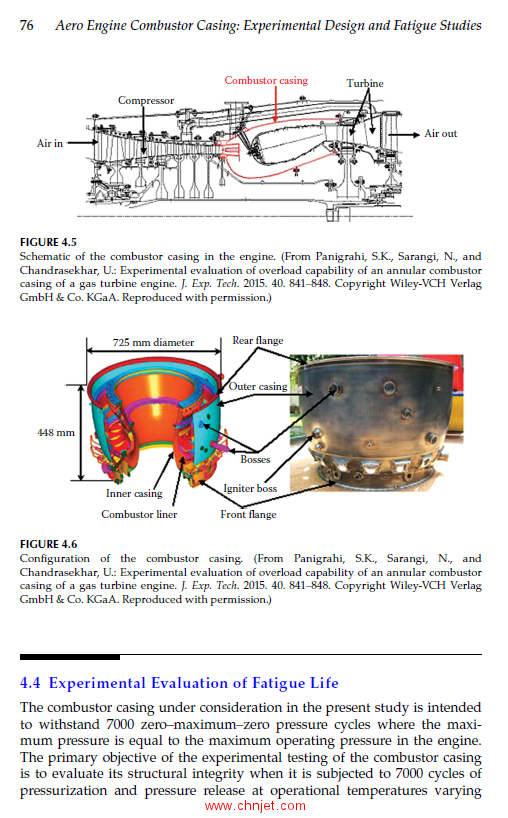

4.3 Configuration of the Combustor Casing..........................................75

4.4 Experimental Evaluation of Fatigue Life.......................................... 76

4.4.1 Instrumentation......................................................................77

4.4.2 Inspection Methodology........................................................79

4.5 Mechanical Properties of Combustor Casing Material.................. 81

4.6 Numerical Analysis of the Combustor Casing................................82

4.6.1 Details of the Finite Element Model.....................................83

4.6.2 Finite Element Model Quality Parameters..........................84

4.6.3 Boundary Conditions.............................................................85

4.6.4 Load..........................................................................................85

4.6.5 Pressure Load..........................................................................85

4.6.6 Thermal Load..........................................................................85

4.6.7 Nusselt Equation..................................................................... 87

4.6.8 Dittus Boelter Equation.......................................................... 87

4.7 Numerical Analysis of the Igniter Boss and Its Correlation

with Experimental Data......................................................................89

4.8 Results and Discussions......................................................................98

4.9 Summary...............................................................................................98

5. Reassessment of Fatigue Life of the Modified

Combustor Casing...................................................................................... 101

5.1 Introduction........................................................................................ 101

5.2 Modified Manufacturing Methodology......................................... 101

5.2.1 Forging Process: Benefits and Drawbacks........................ 101

5.3 Instrumentation of the Modified Combustor Casing................... 106

5.4 Assembly and Trial Run................................................................... 106

5.5 Testing.................................................................................................. 109

5.6 Results and Discussion..................................................................... 109

5.7 Summary............................................................................................. 110

6. Safety Test on Modified Combustor Casing.......................................... 113

6.1 Introduction........................................................................................ 113

6.2 Test Component Details.................................................................... 114

6.3 Instrumentation and Testing............................................................ 115

6.4 Results and Discussion..................................................................... 117

6.5 Summary............................................................................................. 118

7. Effect of Fatigue on the Proof Strength of an Aero Engine

Combustor Casing....................................................................................... 119

7.1 Introduction........................................................................................ 119

7.2 Metallographic Techniques in Failure Analysis............................ 120

7.2.1 Stereo Zoom Microscopy..................................................... 121

7.2.2 Scanning Electron Microscopy........................................... 121

7.2.3 Optical Microscopy.............................................................. 125

7.3 Details of the Test Component......................................................... 126

7.4 Experimental Procedure................................................................... 127

7.5 Observation......................................................................................... 128

7.5.1 Visual Observation............................................................... 128

7.5.2 Stereo Zoom Microscopy..................................................... 128

7.5.3 Scanning Electron Microscopy........................................... 129

7.5.3.1 Fractography.......................................................... 129

7.5.3.2 Energy Dispersive X-Ray Analysis..................... 131

7.5.4 Optical Microscopy.............................................................. 131

7.5.5 Microhardness Measurement............................................. 131

7.6 Discussions......................................................................................... 137

7.7 Summary............................................................................................. 137

8. Conclusions................................................................................................... 139

8.1 Certification and Acceptance of the Combustor Casing.............. 139

8.2 Specific Conclusions.......................................................................... 139

8.3 Scope for Further Work..................................................................... 140

References............................................................................................................ 143

Index...................................................................................................................... 153

专业书籍

下载地址:(回复后可见)

| ![]()