马上注册,结交更多好友,享用更多功能,让你轻松玩转社区。

您需要 登录 才可以下载或查看,没有账号?立即注册

×

《Turbine Blade Investment Casting Die Technology》

涡轮叶片精密铸造模具技术

作者:

Dinghua Zhang

Yunyong Cheng

Ruisong Jiang

Neng Wan

翻译:

Kuidong Huang

Wenhu Wang

Kun Bu

出版社:Springer

出版时间:2018年

《Turbine Blade Investment Casting Die Technology》

《Turbine Blade Investment Casting Die Technology》

《Turbine Blade Investment Casting Die Technology》

《Turbine Blade Investment Casting Die Technology》

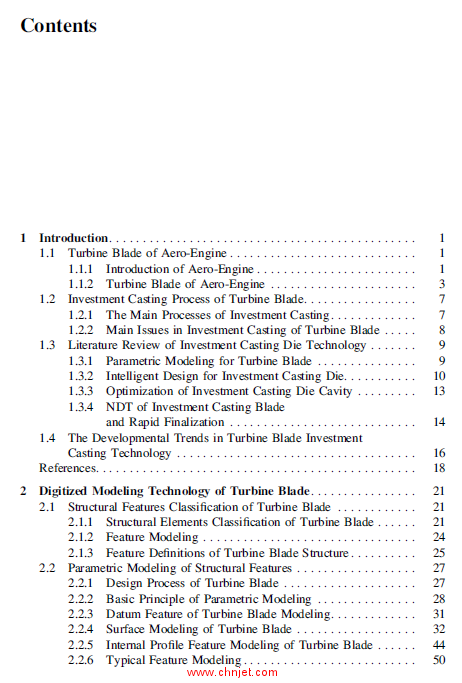

目录

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Turbine Blade of Aero-Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Introduction of Aero-Engine . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.2 Turbine Blade of Aero-Engine . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Investment Casting Process of Turbine Blade. . . . . . . . . . . . . . . . . 7

1.2.1 The Main Processes of Investment Casting . . . . . . . . . . . . . 7

1.2.2 Main Issues in Investment Casting of Turbine Blade . . . . . 8

1.3 Literature Review of Investment Casting Die Technology . . . . . . . 9

1.3.1 Parametric Modeling for Turbine Blade . . . . . . . . . . . . . . . 9

1.3.2 Intelligent Design for Investment Casting Die. . . . . . . . . . . 10

1.3.3 Optimization of Investment Casting Die Cavity . . . . . . . . . 13

1.3.4 NDT of Investment Casting Blade

and Rapid Finalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4 The Developmental Trends in Turbine Blade Investment

Casting Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 Digitized Modeling Technology of Turbine Blade. . . . . . . . . . . . . . . . 21

2.1 Structural Features Classification of Turbine Blade . . . . . . . . . . . . 21

2.1.1 Structural Elements Classification of Turbine Blade . . . . . . 21

2.1.2 Feature Modeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.1.3 Feature Definitions of Turbine Blade Structure . . . . . . . . . . 25

2.2 Parametric Modeling of Structural Features . . . . . . . . . . . . . . . . . . 27

2.2.1 Design Process of Turbine Blade . . . . . . . . . . . . . . . . . . . . 27

2.2.2 Basic Principle of Parametric Modeling . . . . . . . . . . . . . . . 28

2.2.3 Datum Feature of Turbine Blade Modeling. . . . . . . . . . . . . 31

2.2.4 Surface Modeling of Turbine Blade . . . . . . . . . . . . . . . . . . 32

2.2.5 Internal Profile Feature Modeling of Turbine Blade . . . . . . 44

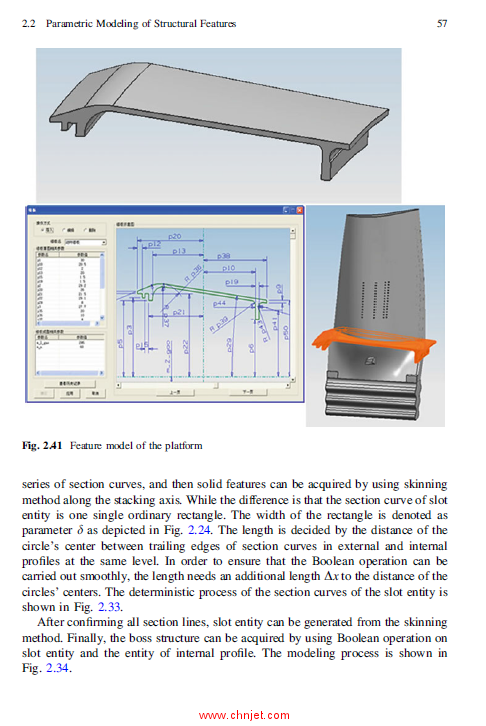

2.2.6 Typical Feature Modeling . . . . . . . . . . . . . . . . . . . . . . . . . . 50

vii

2.3 Case Study . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3 Cavity Design Method for Investment Casting Die of Turbine

Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.1 Multistate Model Transformation Method for Investment

Casting Die Cavity of Turbine Blade . . . . . . . . . . . . . . . . . . . . . . . 63

3.1.1 Definition of Multistate Model of Investment Casting

Die Cavity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3.1.2 Investment Casting Process Driven Multistate Model

Transformation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.1.3 Geometric Information Mapping for Multistate Model

Based on Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.2 Parting Technologies for Investment Casting Die Cavity . . . . . . . . 74

3.2.1 The Parting Principle Based on Feature Decomposition . . . 75

3.2.2 The Die Cavity Feature Decomposition Method . . . . . . . . . 76

3.2.3 Rule-Based Parting Method of Die Cavity . . . . . . . . . . . . . 78

3.3 Design Examples of Investment Casting Die Cavity. . . . . . . . . . . . 82

References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4 Design of the Die Base for the Investment Casting Turbine

Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4.1 Definition and Structure of the Knowledge Template

of Die Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.1.1 Typical Structure of the Base of the Investment

Casting Die . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.1.2 The Definition of the Knowledge Template

for the Die Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4.1.3 Structure and Data Model of the Knowledge Template

for the Die Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.2 The Method to Construct a Knowledge Template

for Investment Casting Die. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4.2.1 The Procedures to Construct a Knowledge Template

for the Die Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4.2.2 Extraction of the Knowledge Template . . . . . . . . . . . . . . . . 95

4.2.3 Customization of the Knowledge Template

for the Die Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4.3 Rapid Design of Investment Casting Die Base Based

on the Knowledge Template. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

4.3.1 Rapid Design Method of the Die Base . . . . . . . . . . . . . . . . 101

4.3.2 Design Example with the Template. . . . . . . . . . . . . . . . . . . 103

References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

viii Contents

5 Deformation Simulation of Investment Casting and Die Cavity

Optimization of Turbine Blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.1 Deformation Simulation of Turbine Blade Investment

Casting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.1.1 Investment Casting Simulation Modeling . . . . . . . . . . . . . . 105

5.1.2 Finite Element Modeling Investment Casting . . . . . . . . . . . 112

5.1.3 Investment Casting Simulation . . . . . . . . . . . . . . . . . . . . . . 115

5.2 The Analysis Calculation of the Simulation of Investment

Casting Deformation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

5.2.1 The Distribution Regularity of Turbine Blade Surface

Size Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

5.2.2 The Definition of the Displacement Field

of Solidification Process . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

5.2.3 The Calculate Method of Displacement Field . . . . . . . . . . . 136

5.2.4 Vector Expression and Vector Resolution of the

Displacement Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

5.2.5 The Establishment of Displacement Field Model . . . . . . . . 141

5.3 Reserve Deformation Optimization and Virtual Mold Repair

of the Mold Cavity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

5.3.1 Calculating Methods of Cavity Size . . . . . . . . . . . . . . . . . . 142

5.3.2 The Method of Reverse Deformation of Cavity . . . . . . . . . 146

5.3.3 Reverse Superposition Method of Grid Displacement

Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

5.3.4 Cavity Optimization Based on Superimposed

Displacement Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

5.3.5 Scaling Method Based on Shrinkage Ratio . . . . . . . . . . . . . 156

5.4 The Rapid Verification Technologies of Cavity Optimization. . . . . 166

5.4.1 Die Cavity Validation Scheme Based on Wax

Pattern NC Machining . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

5.4.2 Wax Material Craft Process and Machining Parameter

Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

5.4.3 NC Machining Post Processing of Wax Material . . . . . . . . 169

References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

6 The Manufacturing and Finalization of the Turbine Blade

Investment Casting Die . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

6.1 The Manufacturing Process of the Turbine Blade Investment

Casting Die. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

6.1.1 The Structural Features of the Turbine Blade Investment

Casting Die . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

6.1.2 The Manufacturing Process of the Turbine Blade

Investment Casting Die . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Contents ix

6.2 The Process Plan of the Turbine Blade Investment

Casting Die. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

6.2.1 Materials Selection for Die Manufacturing . . . . . . . . . . . . . 176

6.2.2 The Process Planning for Die Manufacturing . . . . . . . . . . . 178

6.2.3 The Design of the Second Tooling Electrode . . . . . . . . . . . 182

6.2.4 The Selection of the Process Ball . . . . . . . . . . . . . . . . . . . . 185

6.3 The Machining Technology of the Turbine Blade Investment

Casting Die. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

6.3.1 The Machining Technology . . . . . . . . . . . . . . . . . . . . . . . . 185

6.3.2 Nontraditional Machining Technologies in Die

Manufacturing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

6.3.3 The Surface Treatment Technology. . . . . . . . . . . . . . . . . . . 198

6.3.4 The Repairing Technique . . . . . . . . . . . . . . . . . . . . . . . . . . 204

6.4 The Finalization of the Turbine Blade Investment

Casting Die. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

6.4.1 The Inspection of the Investment Casting Die. . . . . . . . . . . 206

6.4.2 The Testing of the Investment Casting Die . . . . . . . . . . . . . 207

6.4.3 The Finalization of the Investment Casting Die . . . . . . . . . 208

References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

7 Turbine Blade Investment Casting Experiment and Measurement

Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

7.1 Investment Casting Experiment Process . . . . . . . . . . . . . . . . . . . . . 211

7.2 Blade Casting Geometrical Dimension Measurement and

Evaluation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

7.2.1 Measurement Data Acquisition . . . . . . . . . . . . . . . . . . . . . . 213

7.2.2 Model Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

7.2.3 Geometrical Shape Analysis . . . . . . . . . . . . . . . . . . . . . . . . 234

References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

中文版的

《Turbine Blade Investment Casting Die Technology》

专业书籍

下载地址:(回复后可见)

| ![]()