马上注册,结交更多好友,享用更多功能,让你轻松玩转社区。

您需要 登录 才可以下载或查看,没有账号?立即注册

×

《Composite Manufacturing Technology》

复合材料制造技术

作者:

A.G. Bratukhin

Russian Academy of Sciences I Moscow I Russia

v.s. Bogolyubov

Russian Academy of Sciences I Moscow I Russia

出版社:Chapman &: Hall

出版时间:1995年

《Composite Manufacturing Technology》

《Composite Manufacturing Technology》

《Composite Manufacturing Technology》

《Composite Manufacturing Technology》

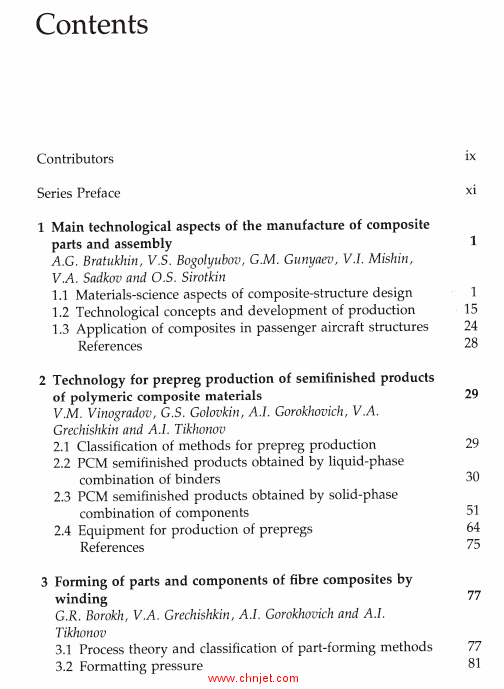

目录

Contributors IX

Series Preface Xl

1 Main technological aspects of the manufacture of composite

parts and assembly 1

A.G. Bratukhin, V.S. Bogolyubov, G.M. Gunyaev, V.I. Mishin,

VA Sadkov and 0.5. Sirotkin

1.1 Materials-science aspects of composite-structure design 1

1.2 Technological concepts and development of production 15

1.3 Application of composites in passenger aircraft structures 24

References 28

2 Technology for prepreg production of semifinished products

of polymeric composite materials 29

V.M. Vinogradov, G.S. Golovkin, A.!. Gorokhovich, V.A.

Grechishkin and A.!. Tikhonov

2.1 Classification of methods for prepreg production 29

2.2 PCM semifinished products obtained by liquid-phase

combination of binders 30

2.3 PCM semifinished products obtained by solid-phase

combination of components 51

2.4 Equipment for production of prepregs 64

References 75

3 Forming of parts and components of fibre composites by

w~~q n

G.R. Borokh, V.A. Grechishkin, A.I. Gorokhovich and A.!.

Tikhonov

3.1 Process theory and classification of part-forming methods 77

3.2 Formatting pressure 81

vi Contents

3.3 Surface reinforcing lines 82

3.4 Classification of winding processes 94

3.5 Factors defining winding-component and prepreg

properties: basic technological conditions and control of

the winding process 99

3.6 Control of the winding process 105

3.7 Equipment for product forming by winding 106

- Principles of operation of equipment. Technical data 106

- Forming of parts and components of fibre composites by

winding 109

3.8 Winding-process automation: process programming on

NC machines and preparation problems in control

programs for reinforcing 118

References 124

4 Shape-forming and curing of composite-material parts 125

G.M. Gunyaev and A.G. Savin

4.1 Physical and chemical mechanisms of vacuum-autoclave

moulding 125

4.2 Mathematical modelling of the structure-manufacturing

process through vacuum-autoclave moulding 130

4.3 Development of working processes in part manufacture by

vacuum-autoclave moulding 149

References 153

5 Machining of polymer-composite materials 155

G.A. Krivov and B.V. Lupkin

5.1 Polymer-composite material (PCM) as the object of

machining 155

5.2 Tool materials and cutting tools for PCM machining 170

5.3 Choice of cutting conditions in PCM machining 194

5.4 Special PCM machining methods with material removal 205

References 217

6 Composite-material part joining 219

0 .5. Sirotkin and V.B . Litvinov

6.1 Joint classification: types of joints and their applications 219

6.2 Mechanical-joint design 222

6.3 Riveted joints in composite-material structures 232

6.4 High-stress bolted joints 252

6.5 Adhesive-joint design 267

6.6 Combined-joint design 274

6.7 Technological developments in joint strength 276

6.8 Technology of riveted-joint formation 280

References 282

Contents vii

7 Non-metallic-based honeycomb cores 284

A.G. Bratukhin, V.S. Bogolyubov, V.A. Razumovsky, A.G. Savin,

V.I. Mishin and V.V. Sadkov

7.1 Polymeric-paper-based honeycomb cores 284

7.2 Fibre-glass-cloth-based honeycomb cores 320

7.3 Honeycomb-core application in aircraft structures 331

References 340

8 Non-destructive testing or composites parts 342

A.D. Denel

8.1 Introduction 342

8.2 Acoustic methods 343

8.3 Microwave method 351

8.4 Electrical methods 355

8.5 Radiation methods 358

8.6 Infrared and thermal methods 360

8.7 Holographic method 364

References 365

9 Three-dimensional tooling 366

V.S. Bogolyubov, A.G. Bratukhin and G.I. Lvov

9.1 Introduction 366

9.2 Design of composite thin-walled tooling for manufacture

of metal-polymeric line-forming parts 367

9.3 Forming tooling-structural diagrams 378

9.4 Design and analysis of thin-walled tooling structures 383

9.5 Shell analysis for the action of local loads 386

9.6 Tooling analysis for the action of functional loads 388

9.7 Supporting-structure wall thickness for stability under

compressive forces 405

9.8 Stiffness analysis and selection of tooling-frame structural

parameters 407

References 422

Index 423

专业书籍

下载地址:(回复后可见)

| ![]()