马上注册,结交更多好友,享用更多功能,让你轻松玩转社区。

您需要 登录 才可以下载或查看,没有账号?立即注册

×

《Probabilistic fracture mechanics and reliability》

概率断裂力学和可靠性

编者:

James W. Provan

Associate Dean, Faculty of Engineering and

Director, Fracture Control Laboratory,

Department of Mechanical Engineering,

McGill University

出版社:Springer

出版时间:1987年

《Probabilistic fracture mechanics and reliability》

《Probabilistic fracture mechanics and reliability》

《Probabilistic fracture mechanics and reliability》

《Probabilistic fracture mechanics and reliability》

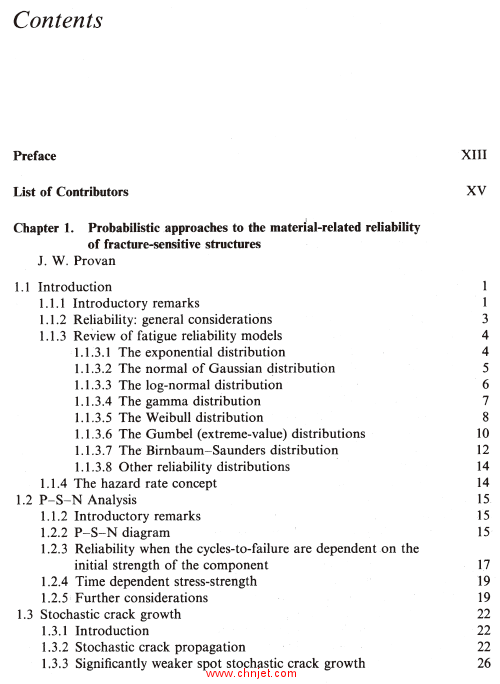

目录

Preface XIII

List of Contributors XV

Chapter 1. Probabilistic .approaches to the matedal-related reliability

of fracture-sensitive structures

J. W. Provan

1.1 Introduction 1

1.1.1 Introductory remarks 1

1.1.2 Reliability: general considerations 3

1.1.3 Review of fatigue reliability models 4

1.1.3.1 The exponential distribution 4

1.1.3.2 The normal of Gaussian distribution 5

1.1.3.3 The log-normal distribution 6

1.1.3.4 The gamma distribution 7

1.1.3.5 The Weibull distribution 8

1.1.3.6 The Gumbel (extreme-value) distributions 10

1.1.3.7 The Birnbaum-Saunders distribution 12

1.1.3.8 Other reliability distributions 14

1.1.4 The hazard rate concept 14

1.2 P-S-N Analysis 15

1.1.2 Introductory remarks 15

1.2.2 P-S-N diagram 15

1.2.3 Reliability when the cycles-to-failure are dependent on the

initial strength of the component 17

1.2.4 Time dependent stress-strength 19

1.2.5 Further considerations 19

1.3 Stochastic crack growth 22

1.3.1 Introduction 22

1.3.2 Stochastic crack propagation 22

1.3.3 Significantly weaker spot stochastic crack growth 26

v

Contents

1.4 The micromechanics approach to fatigue failure 27

1.4.1 Introduction 27

1.4.2 The foundation of micromechanics 27

1.4.2.1 The micromechanic axioms pertaining to fatigue

failure 27

1.4.2.2 Experimental and theoretical studies on the elastic

response of metals 29

1.4.3 Fatigue crack initiation 31

1.4.4 Fatigue crack propagation 32

1.4.5 Fatigue crack experimental investigations 35

1.4.6 Comparison of theoretical and experimental results 36

1.5 A fatigue reliability law based on probabilistic micromechanics 37

1.5.1 Introductory remarks 37

1.5.2 The micromechanics fatigue reliability relation 38

1.5.3 An experimental investigation of fatigue reliability laws 39

1.6 Concluding remarks 44

Chapter 2. Probabilistic damage tolerance analysis of aircraft

structures

B. Palmberg, A. F. Blom and S. Eggwertz

2.1 Introduction

2.2 Basic assumptions

2.3 Load spectra

2.3.1 Specification of loads and environment

2.3.2 Acquisition of load spectra in service

2.3.3 Load sequences, truncations

2.3.4 Scatter considerations

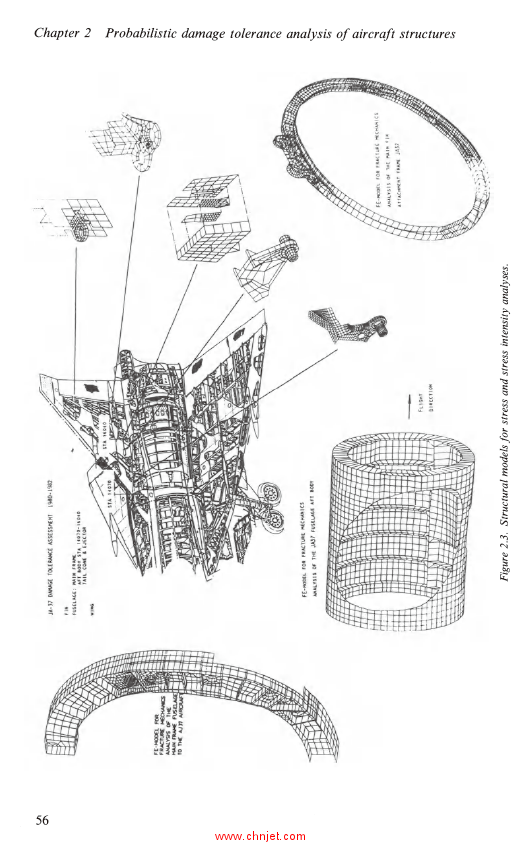

2.4 Stress and stress intensity analysis

2.4.1 Structural models

2.4.2 Available handbook and literature results

2.4.3 Disturbances such as residual stresses, contact stresses,

friction

2.5 Imperfections

2.5.1 Classification of imperfections

2.5.2 Quality control

2.5.3 Equivalent initial flaw sizes

2.5.4 US military damage tolerance requirements

2.6 Crack growth

2.6.1 Constant amplitude crack growth rate

2.6.f Variable amplitude crack growth rate

2.6.3 Variability in crack growth rate

2.6.4 Predicting fatigue crack growth

2.6.5 Stochastic modelling of crack growth

2.7 Fracture mechanics and residual strength

2.7.1 Material behaviour

VI

47

48

49

49

50

52

53

54

54

58

60

62

62

62

63

67

68

68

70

72

73

77

86

86

2.7.2 Linear elastic fracture mechanics

2.7.3 Nonlinear fracture mechanics

2.7.4 Scatter in fracture toughness

2.7.5 Probability of failure

2.8 Inspection during service life

2.8.1 Damage sources and inspection procedures

2.8.2 Probability of crack detection by NDI methods

2.8.3 Length of intervals

2.8.4 US military damage tolerance requirements

2.8.5 Crack size distribution after multiple inspections

2.9 Structural safety

2.9.1 Discussion of USAF damage tolerance requirements

2.9.2 Residual strength of structures

2.9.3 Safety analysis

2.9.4 Numerical example

2.10 Concluding remarks

Chapter 3. Aircraft structural reliability and risk analysis

F. H. Hooke

3.1 Introduction

3.1.1 The reliability concept

3.2 Basic reliability and risk mathematics

3.2.1 Mixed population with different risks

3.3 Physical aspects of structural failure

3.3.1 Loading actions

3.3.2 Structural behaviour

3.4 Mathematical-statistical model representing a real structural

Contents

89

92

95

96

102

102

102

106

107

108

113

113

115

116

118

128

132

133

135

137

139

139

140

situation 142

3.5 Reliability without inspections - the safe life situation 146

3.5.1 Risk of static ultimate load failure 147

3.5.2 Risk of failure with deteriorating strength 148

3.5.3 Partitioning the risk 149

3.5.4 Averaging the instantaneous risk 152

3.5.5 Truncation of the strength - time curve 152

3.5.6 Structures with initial cracks 154

3.5.7 Structures with multiple failure modes and locations 155

3.6 Risk of failure with inspectable structures 156

3.7 Illustrative examples 157

3.7.1 Safe life situation - ultra high strength material 158

3.7.2 Safety-by-inspection situation: typical aluminium alloy

material 160

3.7.2.1 Distribution of strength with virgin strength preserved 160

3.7.2.2 Change of strength distribution with timedeteriorating

strength 161

3.7.2.3 Safety by inspection 162

VII

Contents

3.8 Acceptable risk 164

3.9 Reliability of reliability estimates 165

3.9.1 Confidence intervals related to the sampling of H 166

3.9.2 Confidence regions related to the sampling of (11og H 166

3.9.3 Confidence intervals related to the sampling of Uo 167

3.9.4 Confidence in relation to extrapolation of the spectrum 167

3.9.5 Confidence related to safe-by-inspection structures 168

3.10 General discussion 168

Chapter 4. Stochastic crack growth models for applications to aircraft

structures

J. N. Yang, W. H. Hsi, S. D. Manning, and J. L. Rudd

4.1 Introduction 171

4.2 Stochastic models for fatigue crack propagation 173

4.2.1 Stochastic crack-propagation model 173

4.2.2 Fatigue crack growth data in fastener holes 174

4.2.3 Lognormal crack growth rate model and analysis procedures 176

4.2.4 Lognormal random process model 181

4.2.5 Lognormal white noise model 182

4.2.6 Lognormal random variable model 183

4.2.7 Correlation with experimental test results 186

4.2.7.1 General lognormal random process model 186

4.7.2.2 Lognormal random variable model 189

4.3 Second moment approximation 191

4.3.1 Mean and standard deviation of W(t) 194

4.3.2 Weibull approximation 195

4.3.3 Gamma and other approximations 196

4.3.4 Correlation between second moment approximations and

experimental test results 197

4.4 Fatigue crack propagation in center-cracked specimens 198

4.4.1 Synergistic sine hyperbolic crack growth rate function 201

4.4.2 Stochastic models and second moment approximations 202

4.4.3 Correlations with experimental test results 203

4.5 Factors affecting probabilistic prediction of fatigue crack propagation 206

4.5.1 Fatigue crack growth analysis procedures 206

4.5.2 Equal number of data points for each specimen 207

4.5.3 Data processing procedures 208

4.6 Conclusions and discussions 209

Chapter 5. Durability of aircraft structures

S. D. Manning, J. N. Yang, and J. L. Rudd

5.1 Introduction

5.2 Durability design requirements

5.2.1 Analytical requirements

5.2.2 Experimental requirements

VIII

213

214

215

216

Contents

5.3 Durability analysis criteria 216

5.3.1 Durability critical parts criteria 216

5.3.2 Economic life criteria/guidelines 217

5.4 Durability analysis methodology 219

5.4.1 General description 220

5.4.2 Assumptions and limitations 220

5.4.3 Initial fatigue quality (IFQ) model 221

5.4.3.1 IFQ model equations for Case I (b > I) 224

5.4.3.2 IFQ model equations for Case II (b = 1) 225

5.4.4 Durability analysis procedures 226

5.5 Durability analysis details 227

5.5.1 EIFS distribution 228

5.5.2 Test/fractographic guidelines 229

5.5.2.1 Test guidelines 230

5.5.2.2 Guidelines for fractographic data 232

5.5.3 Fractographic data pooling concepts 232

5.5.4 Determination of EIFSD parameters 234

5.5.4.1 General concepts and guidelines 235

5.5.4.2 Estimation of Qr 236

5.5.4.3 Estimation of a.;, P; and 8; 237

5.5.4.4 Determination of a. and QP 238

5.5.4.5 Estimation of EIFSD parameters and evaluation of

goodness-of-fit 239

5.5.5 Statistical scaling of P parameter 245

5.5.6 Probability of crack exceedance 247

5.5.6.1 Service crack growth master curve 247

5.5.6.2 Crac~ exceedance predictions 249

5.5.7 Formats for presenting durability analysis results 251

5.6 Durability analysis demonstration 251

5.6.1 Fighter lower wing skins 251

5.6.2 Complex-splice specimens subjected to bomber load

spectrum 259

5.7 Comparison of deterministic and probabilistic approaches for

durability analysis 263

5.7.1 Deterministic crack growth approach 263

5.7.2 Probabilistic approach 264

5.7.3 Conceptual comparisons 264

5.7.3.1 Durability analysis based on DCGA 265

5.7.3.2 Durability analysis based on probabilistic approach 265

5.7.4 Conclusions 266

5.8 Summary and concluding remarks 267

Chapter 6. The reliability of pressurized water reactor vessels

R. F. Cameron, G. o. Johnston, and A. B. Lidiard

6.1 Introduction 269

IX

Contents

6.2 Statistics of pressure vessel failure 272

6.2.1 Nuclear primary circuit 274

6.2.2 Non-nuclear vessels 275

6.3 General physical aspects 277

6.3.1 Cracks - their causes, detection and repair 281

6.3.1.1 Causes and incidence of cracks 282

6.3.1.2 Detection of cracks by non-destructive examination 283

6.3.1.3 Repair of cracks 283

6.3.2 Material toughness and failure mechanisms 283

6.3.3 Crack growth by fatigue 287

6.3.4 Transient loadings 290

6.4 Mathematical formulation 291

6.4.1 General expressions for the failure integral 293

6.4.2 Deterministic crack growth 296

6.4.3 Effect of previous loading: the 'cold hydrotest' 298

6.5 The distribution functions of physical quantities 299

6.5.1 The initial crack-size distribution function 299

6.5.1.1 Cracks arising in manufacture 300

6.5.1.2 Efficiency of the detection of cracks 302

6.5.2 Fracture toughness and flow stress 304

6.5.3 Fatigue crack growth and the transfer function 306

6.6 Applications 307

6.6.1 U.S. and European L.W.R.pressure vessel calculations 308

6.6.2 Survey of results and conclusions 309

6.6.2.1 Absolute failure rates 309

6.6.2.2 Dependence of failure rate upon time in servite 311

6.6.2.3 Sensitivity to the crack incidence function 312

6.6.2.4 Sensitivity to fracture toughness 314

6.6.2.5 Sensitivity to stress-intensity function and failure

condition 315

6.6.2.6 Sensitivity to crack growth rates 316

6.6.2.7 Relative effects of different transients 317

6.6.2.8 Relative contributions of different regions of the

vessel 317

6.6.2.9 In-service inspection 318

6.7 Conclusion 318

Appendix 6.1 Failure criterjon in elastic-plastic fracture mechanics

(the R6 method) 320

Appendix 6.2 320

Appendix 6.3 Example calculation of ~ 321

Chapter 7. Applications of PFM in the nuclear industry to reactor

pressure vessel, main coolant piping and steel containment

R. Wellein

7.1 Introduction

x

325

7.2 Reactor pressure vessel

7.2.1 Brittle fracture of the RPV

7.2.2 Defect distributions

7.2.3 Influence of inspections and tests

7.2.4 Results

7.3 Main coolant piping

7.3.1 Leakage of the MCP

7.3.2 Model of the defect distribution in welds

7.3.3 Influence of vibrations

7.4 Steel containment

7.4.1 Two-criteria-approach

7.4.2 Distributions of material properties

7.4.3 Distributions of defect dimensions

7.4.4 Results

7.5 Conclusions

Chapter 8.' Numerical methods in probabilistic fracture mechanics

A. Bruckner

8.1 Introduction

8.2 Processing of input data

8.2.1 Curve fitting

8.2.1.1 Classical statistics

8.2.1.2 Bayesian methods

8.2.2 Extrapolation from incomplete data

8.2.3 Model calculations

8.2.3.1 Model of crack formation in welds

8.2.3.2 Extreme value theory

8.3 Numerical methods for the calculation of failure probabilities

8.3.1 Monte Carlo methods

8.3.1.1 Simulation

8.3.1.2 Random number generators

8.3.2 Variance reduction

8.3.2.1 Crude Monte Carlo

8.3.2.2 Stratified sampling

8.3.2.3 Importance sampling

8.3.3 Applications to probabilistic fracture mechanics

8.3.3.1 Applications of stratified sampling

8.3.3.2 Applications of importance sampling

8.4 Approximation methods

8.4.1 Basic ideas

8.4.1.1 Linear problems with normal distributions

8.4.1.2 Non-linear problems with normal distributions

8.4.2 Non-linear functions g and non-normal distributions

8.4.2.1 Normal tail approximation

Contents

326

327

327

330

330

332

332

333

336

337

337

338

342

346

350

351

352

352

352

355

359

361

361

361

364

364

364

365

365

365

367

369

372

372

372

375

375

377

378

380

380

XI

Contents

8.4.2.2 Alternative iteration schemes

8.4.3 Applications to probabilistic fracture mechanics

381

382

Chapter 9. Probabilistic fracture mechanics

P. M. Besuner

9.1 Introduction 387

390

390

390

391

393

394

394

395

396

398

399

9.2 G~neral discussion

9.2.1 Background

9.2.2 Deterministic foundations

9.3 Statistical basis for PFM

9.4 Engineering models and PFM

9.5 Numerical methods

9.5.1 Discussion

9.5.2 Monte-Carlo methodology

9.5.2.1 Outline of analysis procedures

9.5.2.2 Using the MC program

9.5.2.3 The basic Monte-Carlo simulation method

9.5.2.4 Minimum requirements to improve the MC

computer program 400

9.6 PFM application examples 401

9.6.1 Optimization of safety factors with pure PFM 401

9.6.2 A failure rate prediction with pure PFM 405

9.6.2.1 The deterministic fracture mechanics problem 408

9.6.2.2 Distribution of the input random variables C, Au, Ai 408

9.6.2.3 The probabilistic analysis 410

9.6.2.4 A dependence effect on the N distribution 412

9.6.2.5 Probabilistic addition of crack initiation cycles 413

9.6.3 RFC of inspectable 'hardware with calibrated PFM 415

9.6.3.1 General discussion of turbine disk problem 415

9.6.3.2 Simulation of stress uncertainty 417

9.6.3.3 Simulation of inspection uncertainty 419

9.6.3.4 Simulation of analyses uncertainties 419

9.6.3.5 Results of cost analysis 421

9.6.3.6 New developments in calibrated PFM/RFC 423

9.6.4 CPFM for hard-to-inspect turbine shaft bores 423

9.6.5 Advanced computer application for general calibrated PFM 427

9.6.5.1 Discussion of baseline RFC procedure simulation 430

9.7 Concluding remarks 432

9.7.1 Summary 432

9.7.2 Future considerations 434

9.7.3 Conclusion 436

References 437

Index 461

专业书籍

下载地址:(回复后可见)

| ![]()