马上注册,结交更多好友,享用更多功能,让你轻松玩转社区。

您需要 登录 才可以下载或查看,没有账号?立即注册

×

《Gamma Titanium Aluminide Alloys:Science and Technology》

伽玛钛铝合金:科学技术

作者:Fritz Appel, Jonathan David Heaton Paul,and Michael Oehring

出版社:Wiley

出版时间:2011年

《Gamma Titanium Aluminide Alloys:Science and Technology》

《Gamma Titanium Aluminide Alloys:Science and Technology》

《Gamma Titanium Aluminide Alloys:Science and Technology》

《Gamma Titanium Aluminide Alloys:Science and Technology》

目录

Preface XIII

Figures – Tables Acknowledgement List XV

1 Introduction 1

References 3

2 Constitution 5

2.1 The Binary Ti–Al Phase Diagram 5

2.2 Ternary and Multicomponent Alloy Systems 11

References 20

3 Thermophysical Constants 25

3.1 Elastic and Thermal Properties 25

3.2 Point Defects 27

3.3 Diffusion 29

References 30

4 Phase Transformations and Microstructures 33

4.1 Microstructure Formation on Solidifi cation 33

4.2 Solid-State Transformations 49

4.2.1 β → α Transformation 50

4.2.2 Formation of (α2 + γ) Lamellae Colonies 52

4.2.3 Feathery Structures and Widmannstätten Colonies 60

4.2.4 Massive Transformation 63

References 64

5 Deformation Behavior of Single-Phase Alloys 71

5.1 Single-Phase γ(TiAl) Alloys 71

5.1.1 Slip Systems and Deformation Kinematics 71

5.1.2 Planar Faults 75

5.1.3 Planar Dislocation Dissociations in γ(TiAl) 81

5.1.4 Nonplanar Dissociations and Dislocation Locking 85

VI Contents

5.1.5 Mechanical Twinning in γ(TiAl) 89

5.1.6 Effects of Orientation and Temperature on Deformation of

γ Phase 95

5.2 Deformation Behavior of Single-Phase α2(Ti3Al) Alloys 106

5.2.1 Slip Systems and Deformation Kinematics 106

5.2.2 Effects of Orientation and Temperature on Deformation of α2

Phase 112

5.3 β/B2 Phase Alloys 114

References 118

6 Deformation Behavior of Two-Phase α2(Ti3Al) + γ(TiAl) Alloys 125

6.1 Lamellar Microstructures 125

6.1.1 Interface Structures in Lamellar TiAl Alloys 125

6.1.2 Energetic Aspects of Lamellar Interfaces 136

6.1.3 Coherent and Semicoherent Interfaces 139

6.1.4 Coherency Stresses 149

6.1.5 Plastic Anisotropy 156

6.1.6 Micromechanical Modeling 161

6.2 Deformation Mechanisms, Contrasting Single-Phase and

Two-Phase Alloys 164

6.2.1 Methodical Aspects of TEM Characterization 164

6.2.2 Deformation of (α2 + γ) Alloys at Room Temperature 165

6.2.3 Independent Slip Systems 169

6.2.4 High-Temperature Deformation of (α2 + γ) Alloys 171

6.2.5 Slip Transfer through Lamellae 173

6.3 Generation of Dislocations and Mechanical Twins 178

6.3.1 Dislocation Source Operation in γ(TiAl) 178

6.3.2 Interface-Related Dislocation Generation 184

6.3.3 Twin Nucleation and Growth 186

6.3.4 Twin Intersections 197

6.3.5 Acoustic Emissions 204

6.3.6 Thermal Stability of Twin Structures 206

6.4 Glide Resistance and Dislocation Mobility 207

6.4.1 Thermally Activated Deformation 207

6.4.2 Glide Resistance at the Beginning of Deformation 217

6.4.3 Static and Dynamic Strain Aging of TiAl Alloys 222

6.4.4 Diffusion-Assisted Dislocation Climb, Recovery, and

Recrystallization 232

6.5 Thermal and Athermal Stresses 234

References 240

7 Strengthening Mechanisms 249

7.1 Grain Refi nement 249

7.2 Work Hardening 254

7.2.1 Work-Hardening Phenomena 255

Contents VII

7.2.2 Athermal Contributions to Work Hardening 257

7.2.3 Jog Dragging and Debris Hardening 259

7.2.4 Thermal Stability of Deformation Structures 262

7.2.5 High-Temperature Flow Behavior 268

7.2.6 High Strain-Rate Deformation 272

7.3 Solution Hardening 273

7.3.1 Elemental Size Misfi t of Solute Atoms with the TiAl Matrix 273

7.3.2 Survey of Observations 276

7.3.3 Effect of Solute Niobium 277

7.4 Precipitation Hardening 282

7.4.1 Carbide Precipitation in TiAl Alloys 282

7.4.2 Hardening by Carbides 284

7.4.3 Hardening by Borides, Nitrides, Oxides, and Silicides 289

7.5 Optimized Nb-Bearing Alloys 292

References 295

8 Deformation Behavior of Alloys with a Modulated Microstructure 301

8.1 Modulated Microstructures 301

8.2 Misfi tting Interfaces 306

8.3 Mechanical Properties 310

References 311

9 Creep 313

9.1 Design Margins and Failure Mechanisms 313

9.2 General Creep Behavior 314

9.3 The Steady-State or Minimum Creep Rate 316

9.3.1 Single-Phase γ(TiAl) Alloys 317

9.3.2 Two-Phase α2(Ti3Al) + γ(TiAl) Alloys 319

9.3.3 Experimental Observation of Creep Structures 320

9.4 Effect of Microstructure 322

9.5 Primary Creep 325

9.6 Creep-Induced Degradation of Lamellar Structures 329

9.7 Precipitation Effects Associated with the α2→γ Phase

Transformation 339

9.8 Tertiary Creep 340

9.9 Optimized Alloys, Effect of Alloy Composition and

Processing 341

9.10 Creep Properties of Alloys with a Modulated Microstructure 346

9.10.1 Effect of Stress and Temperature 346

9.10.2 Damage Mechanisms 347

References 352

10 Fracture Behavior 357

10.1 Length Scales in the Fracture of TiAl Alloys 357

10.2 Cleavage Fracture 360

VIII Contents

10.3 Crack-Tip Plasticity 362

10.3.1 Plastic Zone 362

10.3.2 Interaction of Cracks with Interfaces 365

10.3.3 Crack–Dislocation Interactions 367

10.3.4 Role of Twinning 369

10.4 Fracture Toughness, Strength, and Ductility 373

10.4.1 Methodical Aspects 373

10.4.2 Effects of Microstructure and Texture 376

10.4.3 Effect of Temperature and Loading Rate 383

10.4.4 Effect of Predeformation 387

10.5 Fracture Behavior of Modulated Alloys 388

10.6 Requirements for Ductility and Toughness 391

10.7 Assessment of Property Variability 393

10.7.1 Statistical Assessment 393

10.7.2 Variability in Strength and Ductility of TiAl 394

10.7.3 Fracture Toughness Variability of TiAl 396

References 398

11 Fatigue 403

11.1 Defi nitions 403

11.2 The Stress–Life (S–N) Behavior 405

11.3 HCF 407

11.3.1 Fatigue Crack Growth 407

11.3.2 Crack-Closure Effects 409

11.3.3 Fatigue at the Threshold Stress Intensity 411

11.4 Effects of Temperature and Environment on the Cyclic

Crack-Growth Resistance 413

11.5 LCF 418

11.5.1 General Considerations 418

11.5.2 Cyclic-Stress Response 419

11.5.3 Cyclic Plasticity 422

11.5.4 Stress-Induced Phase Transformation and Dynamic

Recrystallization 426

11.6 Thermomechanical Fatigue and Creep Relaxation 428

References 429

12 Oxidation Behavior and Related Issues 433

12.1 Kinetics and Thermodynamics 433

12.2 General Aspects Concerning Oxidation 437

12.2.1 Effect of Composition 437

12.2.2 Mechanical Aspects of Oxide Growth 439

12.2.3 Effect of Oxygen and Nitrogen 441

12.2.4 Effect of Other Environmental Factors 443

12.2.5 Subsurface Zone, the Z-Phase, and Silver Additions 446

12.2.6 Effect of Surface Finish 447

Contents IX

12.2.7 Ion Implantation 448

12.2.8 Infl uence of Halogens on Oxidation 450

12.2.9 Embrittlement after High-Temperature Exposure 450

12.2.10 Coatings/Oxidation-Resistant Alloys 456

12.3 Summary 458

References 459

13 Alloy Design 465

13.1 Effect of Aluminum Content 465

13.2 Important Alloying Elements – General Remarks 467

13.2.1 Cr, Mn, and V 468

13.2.2 Nb, W, Mo, and Ta 469

13.2.3 B, C, and Si 469

13.3 Specifi c Alloy Systems 471

13.3.1 Conventional Alloys 472

13.3.2 High Niobium-Containing Alloys 472

13.3.3 β-Solidifying Alloys 473

13.3.4 Massively Transformed Alloys 474

13.4 Summary 476

References 477

14 Ingot Production and Component Casting 479

14.1 Ingot Production 479

14.1.1 Vacuum Arc Melting (VAR) 480

14.1.2 Plasma-Arc Melting (PAM) 483

14.1.3 Induction Skull Melting (ISM) 489

14.1.4 General Comments 492

14.2 Casting 495

14.2.1 Investment Casting 497

14.2.2 Gravity Metal Mold Casting (GMM) 503

14.2.3 Centrifugal Casting 506

14.2.4 Countergravity Low-Pressure Casting 513

14.2.5 Directional Casting 514

14.3 Summary 515

References 515

15 Powder Metallurgy 521

15.1 Prealloyed Powder Technology 522

15.1.1 Gas Atomization 522

15.1.1.1 Plasma Inert-Gas Atomization (PIGA) at GKSS 524

15.1.1.2 Titanium Gas-Atomizer Process (TGA) 526

15.1.1.3 Electrode Induction Melting Gas Atomization (EIGA) 527

15.1.2 Rotating-Electrode Processes 529

15.1.3 Rotating-Disc Atomization 531

15.1.4 General Aspects of Atomization 532

X Contents

15.1.5 Postatomization Processing 542

15.1.5.1 Hot Isostatic Pressing (HIPing), Hot Working, and

Properties 543

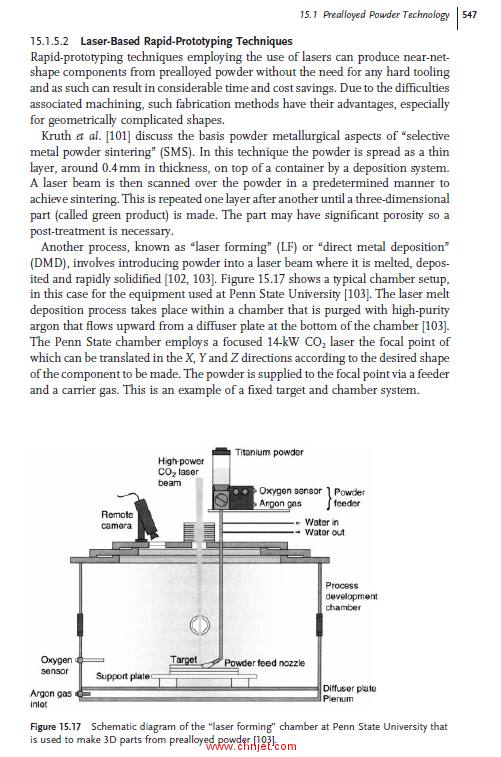

15.1.5.2 Laser-Based Rapid-Prototyping Techniques 547

15.1.5.3 Metal Injection Molding (MIM) 549

15.1.5.4 Spray Forming 551

15.1.5.5 Sheet/Foil Production through (i) HIP of Cast Tapes and

(ii) Liquid-Phase Sintering 556

15.1.5.6 Spark Sintering 557

15.1.6 Summary 558

15.2 Elemental-Powder Technology 559

15.2.1 Reactive Sintering 559

15.2.1.1 Mechanical Properties of Reactive Sintered Material 563

15.2.1.2 Manufacture of Reactively Sintered Components/Parts 564

15.2.2 Summary 564

15.3 Mechanical Alloying 565

References 566

16 Wrought Processing 573

16.1 Flow Behavior under Hot-Working Conditions 574

16.1.1 Flow Curves 574

16.1.2 Constitutive Analysis of the Flow Behavior 578

16.2 Conversion of Microstructure 585

16.2.1 Recrystallization of Single-Phase Alloys 585

16.2.2 Multiphase Alloys and Alloying Effects 587

16.2.3 Infl uence of Lamellar Interfaces 595

16.2.4 Microstructural Evolution during Hot Working above the Eutectoid

Temperature 603

16.2.5 Technological Aspects 605

16.3 Workability and Primary Processing 607

16.3.1 Workability 607

16.3.2 Ingot Breakdown 617

16.4 Texture Evolution 642

16.5 Secondary Processing 658

16.5.1 Component Manufacture through Wrought Processing 658

16.5.2 Rolling – Sheet Production and Selected Mechanical Properties 662

16.5.2.1 Pack Rolling 663

16.5.2.2 Rolling Defects 666

16.5.2.3 Industrial Production of Sheet 667

16.5.2.4 Mechanical Properties of Sheet 668

16.5.2.5 Superplastic Behavior 669

16.5.3 Novel Techniques 671

16.5.3.1 Manufacture of Large “Defect-Free” Components 671

References 673

Contents XI

17 Joining 683

17.1 Diffusion Bonding 683

17.1.1 Alloy Compositions and Microstructures 684

17.1.2 Microasperity Deformation 685

17.1.3 Diffusion Bonding; Experimental Setup 687

17.1.4 Metallographic Characterization of the Bonding Zone 687

17.1.5 Effect of Alloy Composition 696

17.1.6 Infl uence of Bonding Time and Stress 698

17.1.7 Mechanical Characterization of the Bonds 700

17.2 Brazing and Other Joining Technologies 702

17.2.1 Brazing and Transient Liquid-Phase Joining 702

17.2.2 Other Techniques 704

References 704

18 Surface Hardening 707

18.1 Shot Peening and Roller Burnishing 707

18.2 Residual Stresses, Microhardness, and Surface Roughness 708

18.3 Surface Deformation Due to Shot Peening 712

18.4 Phase Transformation, Recrystallization, and Amorphization 716

18.5 Effect of Shot Peening on Fatigue Strength 721

18.6 Thermal Stability of the Surface Hardening 724

References 726

19 Applications, Component Assessment, and Outlook 729

19.1 Aerospace 729

19.1.1 Aircraft-Engine Applications 729

19.1.2 Exotic Aerospace Applications 731

19.2 Automotive 732

19.3 Outlook 736

References 737

Subject Index 739

专业书籍

下载地址:(回复后可见)

| ![]()