马上注册,结交更多好友,享用更多功能,让你轻松玩转社区。

您需要 登录 才可以下载或查看,没有账号?立即注册

×

《Ageing of composites》

复合材料老化

编辑:Rod Martin

出版社:WP

出版时间:2008年

《Ageing of composites》

《Ageing of composites》

《Ageing of composites》

《Ageing of composites》

目录

Contributor contact details xii

Introduction xix

Part I Ageing of composites – processes and

modelling 1

1 The physical and chemical ageing of polymeric

composites 3

T. Gates, formerly NASA Langley Research Center, USA

1.1 Introduction 3

1.2 Background 7

1.3 Viscoelasticity 10

1.4 Ageing and effective time 15

1.5 Development of an ageing study 22

1.6 Summary 28

1.7 References 29

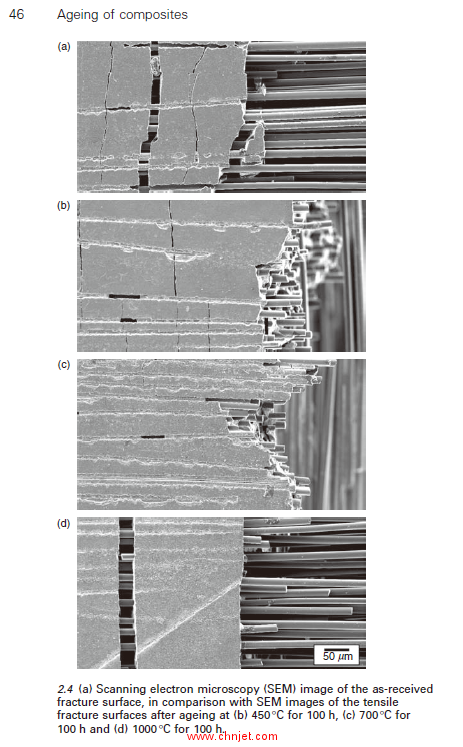

2 Ageing of glass–ceramic matrix composites 34

K. Plucknett, Dalhousie University, Canada

2.1 Introduction 34

2.2 Composite fabrication 42

2.3 Fast-fracture behaviour 42

2.4 Long-term environmental ageing behaviour 43

2.5 Mechanism of oxidation degradation 51

2.6 Development of a failure mechanism map 57

2.7 Oxidation behaviour under applied stress 57

2.8 Thermal shock cycling 62

v

© 2008, Woodhead Publishing Limited except Chapter 6

vi Contents

2.9 Composite protection methods 62

2.10 Conclusions and future trends 63

2.11 References 64

3

reinforced concrete 71

H. Cuypers, Vrije Universiteit Brussel, Belgium;

and J. Orlowsky, Institut für Bauforschung der

RWTH Aachen, Germany

3.1 Introduction 71

72

3.3 Experimental methods 74

3.4 76

3.5 Interface effects 90

3.6 Composite loading effects 91

3.7 In situ degradation of composites due to chemical attack 92

3.8 Conclusions 96

3.9 Acknowledgements 97

3.10 References 97

4 Stress corrosion cracking in glass reinforced

polymer composites 100

A. Chateauminois, Ecole Supérieure de Physique et

Chimie Industrielles (ESPCI), France

4.1 Introduction 100

4.2 Overview of stress corrosion cracking in glass reinforced

polymer matrix composites 101

4.3 107

4.4

reinforced polymer composites 115

4.5 Concluding remarks and future trends 124

4.6 References 126

5 Thermo-oxidative ageing of composite materials 130

T. Tsotsis, The Boeing Company, USA

5.1 Introduction 130

5.2 Developments in understanding thermo-oxidative

ageing 136

5.3 Initial studies – Kerr and Haskins 136

5.4 Overview of other studies 138

5.5 Areas for future study 150

5.6 Conclusions and recommendations 153

5.7 References 154

Chemical ageing mechanisms of glass fibre

3.2 Problem identification

Modelling of the chemical attack of fibres

Stress corrosion cracking of glass fibres

Stress corrosion cracking in unidirectional glass fibre

© 2008, Woodhead Publishing Limited except Chapter 6

Contents vii

6 Fourier transform infrared photoacoustic

spectroscopy of ageing composites 160

R. W. Jones and J. McClelland, Iowa State University,

USA

6.1 Introduction 160

6.2 Theory and practice of photoacoustic spectroscopy 161

6.3 Ageing of composites 170

6.4 Ambient temperature ageing of prepreg 180

6.5 Acknowledgements 180

6.6 References 182

7 Modeling physical ageing in polymer composites 186

H. Hu, National Pingtung University of Science and

Technology, Taiwan

7.1 Introduction 186

7.2 Modeling physical ageing in short-term creep 187

7.3 Modeling physical ageing in long-term creep 200

7.4 Temperature and moisture effects 203

7.5 Conclusions 204

7.6 References 204

8 Ageing of silicon carbide composites 206

S. M. Skolianos, Aristotle University of Thessaloniki,

Greece

8.1 Introduction 206

8.2 Silicon carbide composites 206

8.3 Ageing kinetics 208

8.4 Microstructural change 211

8.5 Effect of volume fraction and size of silicon carbide

reinforcement 214

8.6 Changes in properties 217

8.7 References 220

9 Modelling accelerated ageing in polymer

composites 224

G. Mensitieri, CR-INSTM – University of Naples

Federico II, Italy; and M. Iannone, Alenia Aeronautica

s.p.a., Italy

9.1 Introduction 224

variables 226

9.3 Degradation mechanisms and processes 227

9.4 Modelling time-dependent mechanical behaviour 233

9.2 Definition of environmental conditions and important

© 2008, Woodhead Publishing Limited except Chapter 6

viii Contents

9.5 Modelling mechanical degradation 240

9.6 Modelling physical ageing 241

9.7 Modelling hygrothermal effects 246

9.8 Modelling chemical ageing 254

9.9 Methodology for accelerated testing based on the

modelling approach 256

9.10 Accelerated long-time mechanical behaviour 257

9.11 Accelerated mechanical degradation 270

9.12 Accelerated physical ageing 272

9.13 Accelerated hygrothermal degradation 272

9.14 Accelerated thermal degradation and oxidation 273

9.15 Validation of acceleration procedure by comparison

with real-time data 275

9.16 Future trends 276

9.17 References 276

Part II Ageing of composites in transport applications 283

10 Ageing of composites in the rail industry 285

K. B. Shin, HANBAT National University, Korea

10.1 Introduction 285

10.2 The major environmental ageing factors and their effects

on composites for rail vehicle applications 290

10.3 Environmental test methods and evaluation procedures

for ageing of composites 291

10.4 Case study: evaluation of the effect of increased

composite ageing on the structural integrity of the

bodyshell of the Korean tilting train 302

10.5 Conclusions 308

10.6 References 309

11 Ageing of composites in the rotorcraft industry 311

K. Dragan, Polish Air Force Institute of

Technology, Poland

11.1 Introduction to composite structures applied in the

rotorcraft industry using the example of PZL 311

11.2 Potential damage that can occur in a composite main

rotor blade 313

11.3 Low-energy impact damage and durability in a W-3 main

rotor blade 317

321

11.5 New techniques for testing composite structures 323

11.6 References 324

11.4 Influence of moisture and temperature

© 2008, Woodhead Publishing Limited except Chapter 6

Contents ix

12 Ageing of composites in marine vessels 326

P. Davies and D. Choqueuse, IFREMER Brest

Centre, France

12.1 The use of composites in marine vessels 326

12.2 Marine composites 328

12.3 The marine environment 330

12.4 Recent published studies on marine ageing 331

12.5 Example 1: glass-reinforced thermoset ageing 337

12.6 Example 2: ageing at sea 339

12.7 Example 3: osmosis and blistering 342

12.8 Relevance of accelerated tests 344

12.9 Conclusions and future trends 349

12.10 References 349

Part III Ageing of composites in non-transport

applications 355

13 Ageing of polyethylene composite implants in

medical devices 357

S. Affatato, Istituti Ortopedici Rizzoli, Italy

357

13.2 Brief history of polyethylene used in

medical devices 360

13.3 Improvements on polyethylene for

medical devices 364

13.4 Ageing of polyethylene 367

13.5 Future trends 369

13.6 Acknowledgements 370

13.7 References 370

14 Ageing of composites in oil and gas applications 375

S. Frost, ESR Technology Ltd, UK

14.1 Introduction 375

14.2 Modelling of damage 377

14.3 Ageing due to temperature 384

14.4 Ageing due to chemical species 386

14.5 Ageing due to applied load 389

14.6 Design against ageing 393

14.7 Assessment of ageing 394

14.8 Examples of ageing 397

14.9 Conclusions 398

14.10 References 399

13.1 Definition of medical devices

© 2008, Woodhead Publishing Limited except Chapter 6

x Contents

15 Ageing of composites in the construction industry 401

S. Halliwell, NetComposites Ltd, UK

15.1 Introduction 401

402

405

15.4 Performance requirements 406

15.5 Performance in service 407

15.6 Joints 417

15.7

structures 418

15.8 Summary 418

15.9 Sources of further information and advice 419

15.10 References 419

16 Ageing of composite insulators 421

S. M. Gubanski, Chalmers University of Technology,

Sweden

16.1 High-voltage insulators 421

16.2 Materials and manufacturing techniques 423

16.3 Practical experiences with composite insulators 424

16.4 Ageing of insulator housing 428

16.5 Ageing of insulator cores 439

16.6 Ageing at insulator interfaces 440

16.7 Future trends 442

16.8 Acknowledgements 443

16.9 References 443

17 Ageing of composites in the chemical processing

industry 448

R. Martin, Materials Engineering Research

Laboratory Ltd, UK

17.1 Introduction 448

17.2

chemical processing industry 451

17.3 452

17.4 452

17.5 Current methods for assessing long-term ageing

454

17.6 Case studies of ageing assessment approaches 457

17.7 Concluding remarks 464

17.8 References 465

15.2 Use of fibre-reinforced polymers in construction

15.3 Benefits of fibre-reinforced polymers for construction

Repair of degraded fibre-reinforced polymer composite

Examples of use of fibre reinforced plastics in the

Types of fibre reinforced plastic

Types of degradation in fibre reinforced plastic

of fibre reinforced plastics

© 2008, Woodhead Publishing Limited except Chapter 6

Contents xi

18 Ageing of composites in underwater applications 467

D. Choqueuse and P. Davies, IFREMER Brest Centre,

France

18.1 Introduction 467

18.2 Deep sea environmental parameters 468

18.3 Ageing of composites in water 472

18.4 Case study 1: composite tubes 478

18.5 Case study 2: composite material for deep sea

applications 483

18.6 Case study 3: syntactic foam for deep sea and offshore

applications 489

18.7 Concluding remarks 496

18.8 References 496

专业书籍

下载地址:(回复后可见)

|

![]()