马上注册,结交更多好友,享用更多功能,让你轻松玩转社区。

您需要 登录 才可以下载或查看,没有账号?立即注册

×

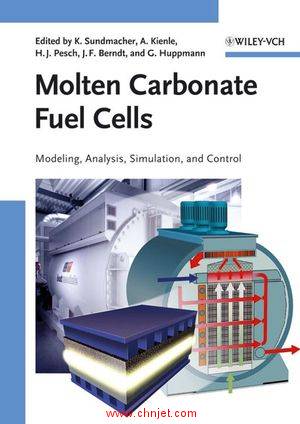

《Molten Carbonate Fuel Cells:Modeling, Analysis, Simulation, and Control》

熔融碳酸盐燃料电池:建模、分析、模拟和控制

编辑:Kai Sundmacher, Achim Kienle, Hans Josef Pesch,Joachim F. Berndt, and Gerhard Huppmann

出版社:Wiley

出版时间:2007年

《Molten Carbonate Fuel Cells:Modeling, Analysis, Simulation, and Control》

《Molten Carbonate Fuel Cells:Modeling, Analysis, Simulation, and Control》

《Molten Carbonate Fuel Cells:Modeling, Analysis, Simulation, and Control》

《Molten Carbonate Fuel Cells:Modeling, Analysis, Simulation, and Control》

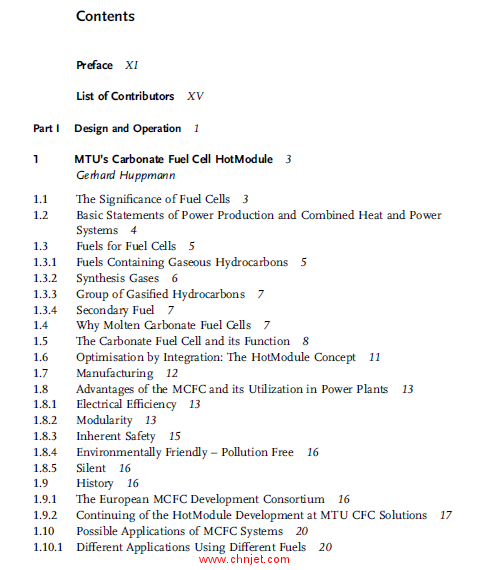

目录

Preface XI

List of Contributors XV

Part I Design and Operation 1

1 MTU’s Carbonate Fuel Cell HotModule 3

Gerhard Huppmann

1.1 The Significance of Fuel Cells 3

1.2 Basic Statements of Power Production and Combined Heat and Power

Systems 4

1.3 Fuels for Fuel Cells 5

1.3.1 Fuels Containing Gaseous Hydrocarbons 5

1.3.2 Synthesis Gases 6

1.3.3 Group of Gasified Hydrocarbons 7

1.3.4 Secondary Fuel 7

1.4 Why Molten Carbonate Fuel Cells 7

1.5 The Carbonate Fuel Cell and its Function 8

1.6 Optimisation by Integration: The HotModule Concept 11

1.7 Manufacturing 12

1.8 Advantages of the MCFC and its Utilization in Power Plants 13

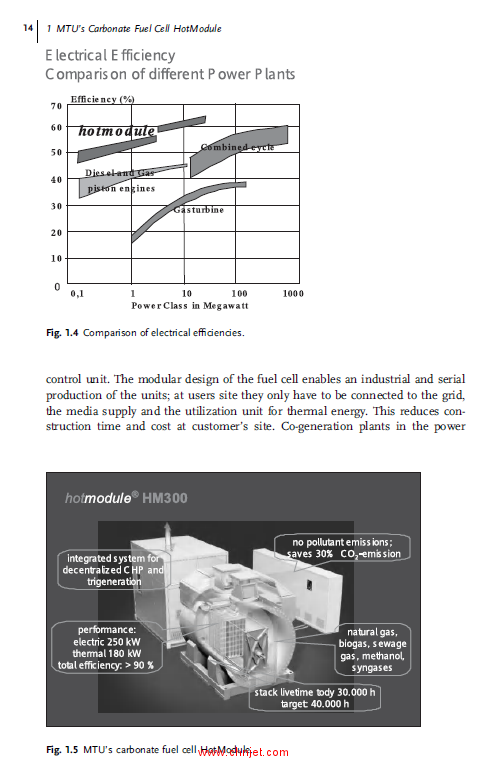

1.8.1 Electrical Efficiency 13

1.8.2 Modularity 13

1.8.3 Inherent Safety 15

1.8.4 Environmentally Friendly – Pollution Free 16

1.8.5 Silent 16

1.9 History 16

1.9.1 The European MCFC Development Consortium 16

1.9.2 Continuing of the HotModule Development at MTU CFC Solutions 17

1.10 Possible Applications of MCFC Systems 20

1.10.1 Different Applications Using Different Fuels 20

V

1.10.2 Different Applications Using the Different Products of the MCFC

System 23

1.11 Economical Impacts 25

2 Operational Experiences 27

Mario Koch, Joachim Berndt, and Matthias Gundermann

2.1 Combined Heat and Power Plant of the Company IPF in Magdeburg 27

2.2 The HotModule in Magdeburg 27

2.3 Operation Experience 30

2.4 Results and Outlook 32

Part II Model-based Process Analysis 33

3 MCFC Reference Model 35

Peter Heidebrecht, and Kai Sundmacher

3.1 Model Hierarchy 35

3.2 General 36

3.3 Model Equations 40

3.3.1 Indirect Internal Reformer 41

3.3.2 Anode Channel 43

3.3.3 Combustion Chamber 45

3.3.4 Reversal Chamber 48

3.3.5 Cathode Channels 49

3.3.6 Electrode Pores 51

3.3.7 Solid Phase 53

3.3.8 Electric Potential 55

3.3.9 Reaction Kinetics 57

3.3.10 Thermodynamics 59

3.4 Summary 61

Bibliography 61

4 Index Analysis of Models 63

Kurt Chudej, Hans Josef Pesch, and Joachim Rang

4.1 Differential Time Index 63

4.2 MOL Index 68

4.3 Perturbation Index 69

4.3.1 Transformation to Homogenous Dirichlet Boundary Conditions 69

4.3.2 Abstract Problem 70

4.3.3 Perturbation Index 70

4.3.4 Garding-Type Inequality 71

4.3.5 Estimate for v andv 71

4.3.6 Estimate for u, w and w with Garding-Type Inequality 72

4.4 Conclusion 73

Bibliography 73

VI Contents

5 Parameter Identification 75

Matthias Gundermann and Kai Sundmacher

5.1 Experimental Work 75

5.1.1 Measurement of Cell Current and Cell Voltage 76

5.1.2 Temperature Measurement 76

5.1.3 Measurement of Concentrations 79

5.1.4 Measurement of Flow Rates 80

5.1.5 Conversion of the Measurements into Dimensionless Values 81

5.1.6 Measurement Errors 81

5.1.7 Measuring Campaigns 83

5.2 Strategy for Parameter Estimation 84

5.2.1 Determination of Relevant Parameters 84

5.2.2 Balancing of the Fuel Cell Plant 86

5.2.3 Sensitivity Analysis 93

5.2.4 Parameter Estimation for a Single Load Case 97

5.2.5 Parameter Estimation for the Whole Operating Range 99

5.2.6 Temperature Dynamics 103

5.3 Results of the Parameter Identification 104

5.3.1 Steady State Measurements 104

5.3.2 Plant Balancing and Error Minimisation 107

5.3.3 Parameter Estimation 109

5.3.4 Dynamic Measurements 113

5.3.5 Estimation of the Solid Heat Capacity 116

5.3.6 Evaluation of the Results 117

5.4 Summary 122

Bibliography 123

6 Steady State and Dynamic Process Analysis 125

Peter Heidebrecht, Matthias Gundermann, and Kai Sundmacher

6.1 Steady State Simulation 125

6.2 Current–Voltage Curve 132

6.3 Transient Simulation 133

6.4 Summary 139

Bibliography 140

7 Hot Spot Formation and Steady State Multiplicities 141

Michael Krasnyk, Michael Mangold, Achim Kienle, and Kai Sundmacher

7.1 Introduction 141

7.2 Models Nonlinear Analysis 143

7.2.1 Spatially Distributed Model 143

7.2.2 Lumped Model 145

7.3 Analysis of the Lumped FC Model 146

7.4 Analysis of the Spatially Distributed FC Model 152

Contents VII

7.5 Analysis of a More General High Temperature Fuel Cell Model 154

7.6 Conclusions 157

7.7 Appendix: Model Equations for Nonlinear Analysis 158

7.7.1 Equations of the Spatially Distributed Model 158

7.7.2 Equations of the Lumped Model 161

7.3.3 Model Parameters 162

Bibliography 162

8 Conceptual Design and Reforming Concepts 165

Peter Heidebrecht and Kai Sundmacher

8.1 Steady State Anode Model 166

8.1.1 General 166

8.1.2 Equations 167

8.1.3 Conversion Diagram 170

8.2 Applications of the Steady State Anode Model 173

8.2.1 Comparison of Reforming Concepts 173

8.2.2 Fuel Cell Cascades 175

8.2.3 Anode Exhaust Gas Recycling 178

8.2.4 Fuel Gas Sidefeed 179

8.3 Summary 181

Bibliography 182

Part III Optimization and Advanced Control 183

9 Model Reduction and State Estimation 185

Markus Gro¨tsch, Michael Mangold, Min Sheng, and Achim Kienle

9.1 Introduction 185

9.2 Development of a Nonlinear Reduced Model 186

9.2.1 Choice of Basis Functions 188

9.2.2 Treatment of Boundary Conditions 190

9.2.3 Resulting Reduced Model of the HotModule 191

9.3 Investigation of Observability 192

9.4 Design of an Extended Kalman Filter 193

9.5 Simulation Results 196

9.6 Experimental Results 196

9.7 Conclusions 197

Bibliography 199

10 Optimal Control Strategies 201

Kati Sternberg, Kurt Chudej, and Hans Josef Pesch

10.1 Model and Simulation Setting 202

10.2 Mathematical Methods 204

10.3 Optimal Control of a Load Change 205

10.4 Summary and Conclusion 209

Bibliography 209

VIII Contents

11 Optimisation of Reforming Catalyst Distribution 211

Peter Heidebrecht and Kai Sundmacher

11.1 Introduction 211

11.2 Objective Functions and Optimisation Parameters 212

11.3 Numerical Aspects 214

11.4 Results 216

11.4.1 Optimisation of Input Conditions at Constant Catalyst Density 216

11.4.2 Optimisation of the Reforming Catalyst Density Distribution 218

11.4.3 Optimisation of the Input Conditions for a System with Optimised

Catalyst Density 219

11.5 Summary 220

Bibliography 220

Appendices 221

A List of Symbols 223

B Benchmark Problem: Complete Set of Equations and Parameters 227

Peter Heidebrecht

B.1 Equations 227

B.2 Parameters 227

Index 235

专业书籍

下载地址:(回复后可见)

|

![]()