Testing

The engine was soon installed onto the test rig and had the fuel and electrical cables hooked up, the ECU and fuel pump plus filter connected and battery plugged in, a 3-cell,9.9 V 2100 mAh pack being used for all the test runs. Programming the ECU to the radio being used is very simple, as is priming the fuel line up to the engine, the tubing being disconnected from the turbine whilst this was being done to eliminate any possibility of flooding the turbine with fuel, in this case using my standard fuel mix of Kerosene with 5% Mobil II oil, although of course the engine will also run very happily on Diesel, in common with all other KingTech turbines.

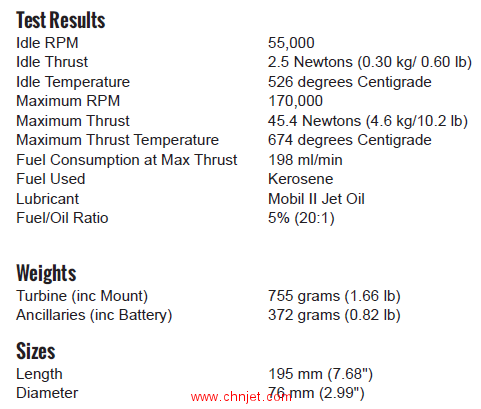

The first start from cold took just over 1 minute, and this was typical for further cold starts, the time for starts from warm being slightly shorter. Nothing untoward was evident, the engine just going through the various stages smoothly until the start sequence was complete and the ECU passed control over to the radio.

The engine was allowed to idle for a period to enable the ECU to more accurately stabilise the exact idle rpm, then the throttle was opened gradually to full, and the engine accelerated up to just below full rpm, the ECU then steadily increasing the power until full power was reached, this process setting the full power rpm and overall throttle range.

With the power reduced to idle the test process was started, with the engine being run at a range of power settings, where thrust,EGT and full consumption were measured. All of this was completed without any fuss, the engine performing very well throughout, even at the top of the power range. The engine ran very smoothly throughout the rpm range with good stability at the various points in the rpm range used to record data.

Acceleration was good at around 4.5 seconds,with deceleration taking a similar time, these figures being very slightly down on some of the recent KingTech engines I have tested, which had outstanding acceleration/deceleration performance. The corrected full power figure of 4.1 kg thrust was however some little way below the 4.5 kg claimed, although the engine was running at the full rated rpm.

Also well below the suggested level was the full throttle fuel consumption at only 143 grams (178 cc) per minute instead of the 155 grams shown in the K-45G specification.

Concerned about these performance figures, which suggested that the engine was running below its optimum performance I spoke to John Wright, who had also recently bought a K-45G. He then kindly ran his engine on his own test rig, and obtained almost identical figures, which confirmed that there was more performance to be had.

A brief email discussion with the factory ensued, the outcome being that the ECU was unlocked to allow an increase in maximum rpm – the standard limit was 162,000, however the factory advised that the compressor was safe well beyond this level.

In the event I set the new maximum rpm to 170,000, this still being well below the safe rpm limit for the compressor. Running the engine at this new maximum rpm was equally uneventful, but of course the thrust and fuel consumption both increased significantly, with the new maximum power being a corrected 4.6 kg, whilst consuming 160 grams per minute, matching the claimed figures almost exactly. The exhaust gas temperature was still relatively low at a maximum of 674°,suggesting that the engine was still running quite conservatively, with performance in hand.

Supplied with the turbine is this very compact fuel pump, manufactured by HP-Tech

Supplied with the turbine is this very compact fuel pump, manufactured by HP-Tech

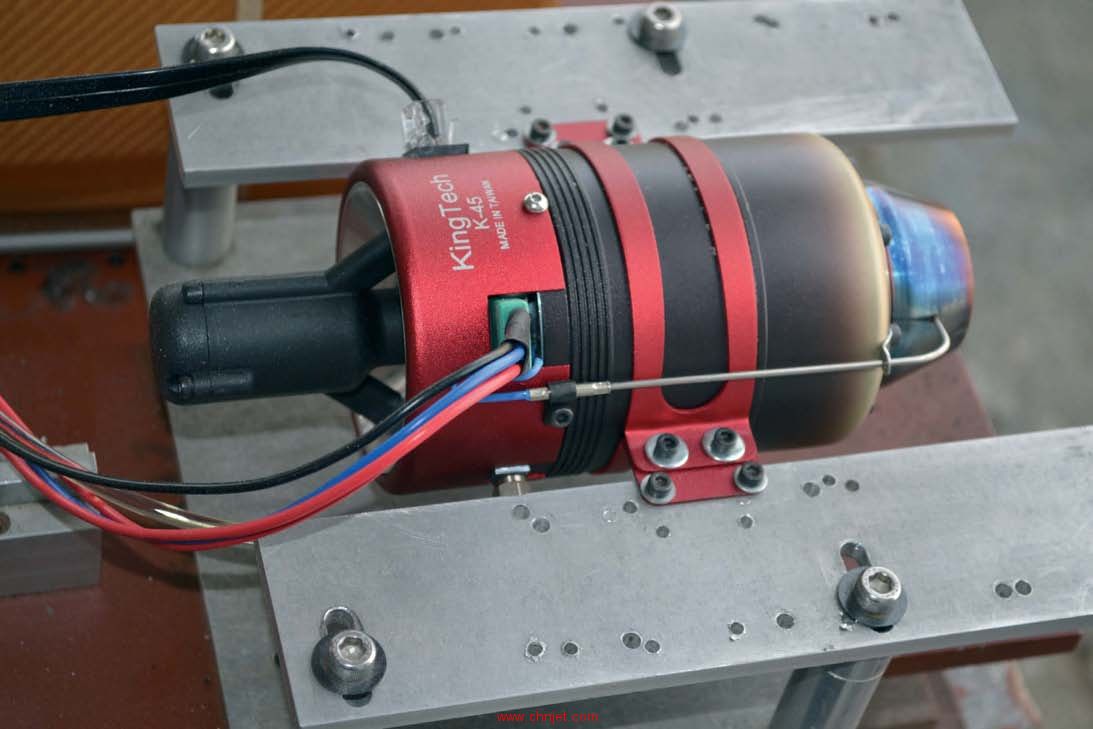

Turbine mounted on the test rig and ready to go for its first test run

Turbine mounted on the test rig and ready to go for its first test run

|

![]()