马上注册,结交更多好友,享用更多功能,让你轻松玩转社区。

您需要 登录 才可以下载或查看,没有账号?立即注册

×

《Micro & Nano-Engineering of Fuel Cells》

燃料电池的微纳工程

编辑:

DennisY.C. Leung

Department of Mechanical Engineering, The University of Hong Kong,

Pokfulam Road, Hong Kong

Jin Xuan

Institute of Mechanical, Process and Energy Engineering, School of Engineering and

Physical Sciences, Heriot-Watt University, Edinburgh, UK

出版社:CRC

出版时间:2015年

《Micro & Nano-Engineering of Fuel Cells》

《Micro & Nano-Engineering of Fuel Cells》

《Micro & Nano-Engineering of Fuel Cells》

《Micro & Nano-Engineering of Fuel Cells》

目录

About the book series vii

Editorial board ix

List of contributors xxvii

Preface xxix

About the editors xxxiii

1. Pore-scale water transport investigation for polymer electrolyte membrane (PEM) fuel cells 1

Takemi Chikahisa &Yutaka Tabe

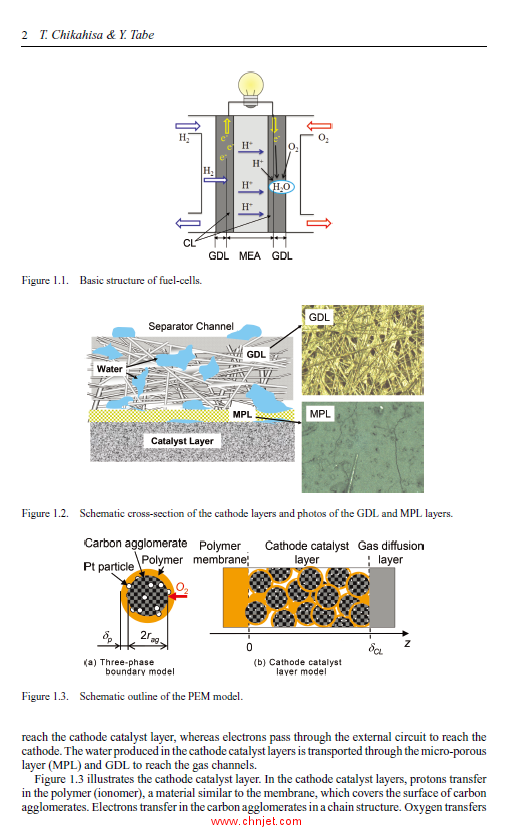

1.1 Introduction 1

1.2 Basics of cell performance and water management 1

1.3 Water transport in the cell channels 4

1.3.1 Channel types 4

1.3.2 Observation of water production, temperatures, and current

density distributions 5

1.3.3 Characteristics of porous separators 9

1.4 Water transport in gas diffusion layers 11

1.4.1 Water transport with different anisotropic fiber directions of the GDL 12

1.4.2 Water transport simulation in GDLs with different wettability gradients 14

1.5 Water transport through micro-porous layers (MPL) 16

1.5.1 Effect of the MPL on the cell performance 16

1.5.2 Observation of the water distribution in the cell 18

1.5.3 Analysis of water transport through MPL 20

1.5.4 Mechanism for improving cell performance with an MPL 21

1.6 Transport phenomena and reactions in the catalyst layers 22

1.6.1 Introduction 22

1.6.2 Analysis model and formulation 23

1.6.3 Results of analysis and major parameters in CL affecting performance 25

1.7 Water transport in cold starts 28

1.7.1 Cold start characteristics and the effect of the start-up temperature 28

1.7.2 Observation of ice distribution and evaluation of the freezing mechanism 30

1.7.3 Strategies to improve cold start performance 31

1.8 Summary 33

2. Reconstruction of PEM fuel cell electrodes with micro- and nano-structures 37

Ulises Cano-Castillo & Romeli Barbosa-Pool

2.1 Introduction 37

2.1.1 The technology: complex operational features required 37

2.1.1.1 Nano-technology to the rescue? 38

2.1.1.2 Challenges: technical and economic goals still remain 39

2.2 Catalyst layers’ structure: a reason to reconstruct 39

2.2.1 Heterogeneous materials 40

xxi

xxii Table of contents

2.2.2 First steps for the reconstruction of catalyst layers 40

2.2.2.1 Structural features matter 41

2.2.2.2 Scaling – a matter of perspectives 42

2.2.3 Stochastic reconstruction – scaling method 43

2.2.3.1 Statistical signatures 44

2.2.4 Let’s reconstruct 45

2.2.4.1 Features of reconstructed structures 47

2.2.4.2 Effective ohmic conductivity 49

2.2.4.3 CL voltage distribution, electric and ionic transport

coefficients 50

2.2.5 Structural reconstruction: annealing route 53

2.2.5.1 Image processing for statistical realistic information 54

2.2.5.2 Structural reconstruction – annealing method 55

2.2.5.3 Statistical functions – two scales 57

2.2.5.4 Effective electric resistivity simulation from a reconstructed

structure 59

2.3 New material support and new catalyst approaches 60

2.3.1 Carbon nanotubes “decorated” with platinum 60

2.3.1.1 Substantial differences for CNT structures 60

2.3.1.2 CNT considerations when inputting component properties 63

2.3.2 Core-shell-based catalyzers 64

2.3.2.1 General considerations for reconstruction 64

2.4 Concluding remarks 64

3. Multi-scale model techniques for PEMFC catalyst layers 69

Yu Xiao, Jinliang Yuan & Ming Hou

3.1 Introduction 69

3.1.1 Physical and chemical processes at different length and time scales 69

3.1.2 Needs for multi-scale study in PEMFCs 69

3.2 Models and simulation methods at different scales 70

3.2.1 Atomistic scale models at the catalyst surface 70

3.2.1.1 Dissociation and adsorption processes on the Pt surface 71

3.2.1.2 Reaction thermodynamics 71

3.2.2 Modeling methods at nano-/micro-scales 72

3.2.2.1 Molecular dynamics modeling method 73

3.2.2.2 Monte Carlo methods 74

3.2.3 Models at meso-scales 74

3.2.3.1 Dissipative particle dynamics (DPD) 74

3.2.3.2 Lattice Boltzmann method (LBM) 75

3.2.3.3 Smoothed particle hydrodynamics (SPH) method 75

3.2.4 Simulation methods at macro-scales 76

3.3 Multi-scale model integration technique 76

3.3.1 Integration methods on atomistical scale to nano-scale 76

3.3.2 Microscopic CL structure simulation 79

3.3.3 Analyses of predicted CLs microscopic structures 79

3.3.3.1 Microscopic parameters evaluation 79

3.3.3.2 Primary pore structure analysis 81

3.3.4 Model validation 82

3.3.4.1 Pore size distribution 82

3.3.4.2 Pt particle size distribution 83

3.3.4.3 The average active Pt surface areas 84

3.3.5 Coupling electrochemical reactions in CLs 87

Table of contents xxiii

3.4 Challenges in multi-scale modeling for PEMFC CLs 88

3.4.1 The length scales 88

3.4.2 The time scales 88

3.4.3 The integration algorithms 88

3.5 Conclusions 89

4. Fabrication of electro-catalytic nano-particles and applications to proton

exchange membrane fuel cells 95

Maria Victoria Martínez Huerta & Gonzalo García

4.1 Introduction 95

4.2 Overview of the electro-catalytic reactions 96

4.2.1 Hydrogen oxidation reaction 96

4.2.2 H2/CO oxidation reaction 96

4.2.3 Methanol oxidation reaction 98

4.2.4 Oxygen reduction reaction 99

4.3 Novel nano-structures of platinum 100

4.3.1 State-of-the-art supported Pt catalysts 100

4.3.2 Surface structure of Pt catalysts 101

4.3.3 Synthesis and performance of Pt catalysts 101

4.4 Binary and ternary platinum-based catalysts 105

4.4.1 Electro-catalysts for CO and methanol oxidation reactions 105

4.4.2 Electro-catalysts for the oxygen reduction reaction 108

4.4.3 Synthetic methods of binary/ternary catalysts 109

4.5 New electro-catalyst supports 112

4.6 Conclusions 115

5. Ordered mesoporous carbon-supported nano-platinum catalysts: application in

direct methanol fuel cells 131

Parasuraman Selvam & Balaiah Kuppan

5.1 Introduction 131

5.2 Ordered mesoporous silicas 132

5.3 Ordered mesoporous carbons 135

5.3.1 Hard-template approach 137

5.3.2 Soft-template approach 139

5.4 Direct methanol fuel cell 140

5.5 Electrocatalysts for DMFC 144

5.5.1 Bulk platinum catalyst 144

5.5.2 Platinum alloy catalyst 145

5.5.3 Nano-platinum catalyst 145

5.5.4 Catalyst promoters 145

5.6 OMC-supported platinum catalyst 145

5.6.1 Pt/NCCR-41 147

5.6.2 Pt/CMK-3 150

5.7 Summary and conclusion 153

6. Modeling the coupled transport and reaction processes in a

micro-solid-oxide fuel cell 159

Meng Ni

6.1 Introduction 159

6.2 Model development 160

6.2.1 Computational fluid dynamic (CFD) model 161

6.2.2 Electrochemical model 163

6.2.3 Chemical model 164

xxiv Table of contents

6.3 Numerical methodologies 165

6.4 Results and discussion 167

6.4.1 Base case 167

6.4.2 Temperature effect 171

6.4.3 Operating potential effect 172

6.4.4 Effect of electrochemical oxidation rate of CO 176

6.5 Conclusions 176

7. Nano-structural effect on SOFC durability 181

YaoWang & Changrong Xia

7.1 Introduction 181

7.2 Aging mechanism of SOFC electrodes 181

7.2.1 Aging mechanism of the anodes 181

7.2.1.1 Grain coarsening 182

7.2.1.2 Redox cycling 185

7.2.1.3 Coking and sulfur poison 185

7.2.2 Aging mechanism of cathodes 186

7.3 Stability of nano-structured electrodes 188

7.3.1 Fabrication and electrochemical properties of nano-structured electrodes 188

7.3.2 Models about nano-structured effects on stability 188

7.3.2.1 Nano-size effects on isothermal grain growth 190

7.3.2.2 Nano-structured effects on durability against thermal cycle 190

7.4 Long-term performance of nano-structured electrodes 192

7.4.1 Anodes 192

7.4.1.1 Enhanced interfacial stabilities of nano-structured anodes 192

7.4.1.2 Durability of nano-structured anodes against redox cycle 195

7.4.1.3 Durability of nano-structured anodes against coking and

sulfur poisoning 196

7.4.2 Cathodes 199

7.4.2.1 LSM 199

7.4.2.2 LSC 200

7.4.2.3 LSCF 202

7.4.2.4 SSC 203

7.5 Summary 204

8. Micro- and nano-technologies for microbial fuel cells 211

Hao Ren & Junseok Chae

8.1 Introduction 211

8.2 Electricity generation fundamental 212

8.2.1 Electron transfer of exoelectrogens 212

8.2.2 Voltage generation 213

8.2.3 Parameter for MFC characterization 214

8.2.3.1 Open circuit voltage (EOCV) 214

8.2.3.2 Areal/volumetric current density (imax,areal, imax,volumetric) and

areal/volumetric power density (pmax,areal, pmax,volumetric) 214

8.2.3.3 Internal resistance (Ri) and areal resistivity (ri) 214

8.2.3.4 Efficiency – Coulombic efficiency (CE) and energy conversion

efficiency (EE) 215

8.2.3.4.1 Coulombic efficiency (CE) 215

8.2.3.4.2 Energy conversion efficiency (EE) 216

8.2.3.5 Biofilm morphology 216

8.3 Prior art of miniaturized MFCs 217

Table of contents xxv

8.4 Promises and future work of miniaturized MFCs 220

8.4.1 Promises 220

8.4.2 Future work 222

8.4.2.1 Further enhancing current and power density 222

8.4.2.2 Applying air-cathodes to replace potassium ferricyanide 223

8.4.2.3 Reducing the cost of MFCs 224

8.5 Conclusion 224

9. Microbial fuel cells: the microbes and materials 227

Keaton L. Lesnik & Hong Liu

9.1 Introduction 227

9.2 How microbial fuel cells work 227

9.3 Understanding exoelectrogens 228

9.3.1 Origins of microbe-electrode interactions 228

9.3.2 Extracellular electron transfer (EET) mechanisms 229

9.3.2.1 Redox shuttles/mediators 229

9.3.2.2 c-type cytochromes 230

9.3.2.3 Conductive pili 231

9.3.3 Interactions and implications 231

9.4 Anode materials and modifications 231

9.4.1 Carbon-based anode materials 232

9.4.2 Anode modifications 233

9.5 Cathode materials and catalysts 234

9.5.1 Cathode construction 234

9.5.2 Catalysts 235

9.5.3 Cathode modifications 235

9.5.4 Biocathodes 236

9.6 Membranes/separators 236

9.7 Summary 238

9.8 Outlook 238

10. Modeling and analysis of miniaturized packed-bed reactors

for mobile devices powered by fuel cells 245

Srinivas Palanki & Nicholas D. Sylvester

10.1 Introduction 245

10.2 Reactor and fuel cell modeling 245

10.2.1 Design equations of the reactor 245

10.2.2 Design equations for the fuel cell stack 246

10.3 Applications 247

10.3.1 Methanol-based system 247

10.3.2 Ammonia-based system 252

10.4 Conclusions 255

11. Photocatalytic fuel cells 257

Michael K.H. Leung, BinWang, Li Li &Yiyi She

11.1 Introduction 257

11.2 PFC concept 257

11.2.1 Fuel cell 257

11.2.2 Photocatalysis 257

11.2.3 Photocatalytic fuel cell 258

11.3 PFC architecture and mechanisms 258

11.3.1 Cell configurations 258

xxvi Table of contents

11.3.2 Bifunctional photoanode 258

11.3.2.1 Photocatalyst 258

11.3.2.2 Substrate materials 260

11.3.2.3 Catalyst deposition methods 261

11.3.3 Cathode 262

11.4 Electrochemical kinetics 263

11.4.1 Current-voltage characteristics 263

11.4.1.1 Ideal thermodynamically predicted voltage 265

11.4.1.2 Activation losses 265

11.4.1.3 Ohmic losses 266

11.4.1.4 Concentration losses 267

11.4.2 Efficiency of a photocatalytic fuel cell 269

11.4.2.1 Pseudo-photovoltaic efficiency 269

11.4.2.2 External quantum efficiency 269

11.4.2.3 Internal quantum efficiency 269

11.4.2.4 Current doubling effect 269

11.5 PFC applications 270

11.5.1 Wastewater problems 270

11.5.2 Practical micro-fluidic photocatalytic fuel cell (MPFC) applications 270

11.6 Conclusion 270

12. Transport phenomena and reactions in micro-fluidic aluminum-air fuel cells 275

HuizhiWang, Dennis Y.C. Leung, Kwong-Yu Chan, Jin Xuan & Hao Zhang

12.1 Introduction 275

12.2 Mathematical model 276

12.2.1 Problem description 276

12.2.2 Cell hydrodynamics 277

12.2.3 Charge conservation 278

12.2.4 Ionic species transport 279

12.2.5 Electrode kinetics 280

12.2.5.1 Anode kinetics 280

12.2.5.2 Cathode kinetics 280

12.2.5.3 Expression of overpotentials 282

12.2.6 Boundary conditions 282

12.3 Numerical procedures 282

12.4 Results and discussion 283

12.4.1 Model validation 283

12.4.2 Hydrogen distribution 284

12.4.3 Velocity distribution 287

12.4.4 Species distribution 287

12.4.4.1 Single-phase flow 287

12.4.4.1.1 Ionic species concentration distributions 287

12.4.4.1.2 Migration contribution to transverse species

transport 288

12.4.4.2 The effect of bubbles 289

12.4.5 Current density and potential distributions 290

12.5 Conclusions 293

专业书籍

下载地址:(回复后可见)

| ![]()